Discover the Why Behind Product Failures—

Build Stronger, More Reliable Metals

When a product fails, the questions start flooding in: Why did it happen? Could it have been prevented? How do we make sure it never happens again?

At Secat, we believe that every failure tells a story—and if you listen carefully, that story holds the key to smarter designs, better materials, and more robust processes.

We specialize in aluminum with the ability to test and analyze any metal. Our failure analysis digs deep beneath the surface to uncover root causes. We use a science-driven, systematic approach that not only fixes the problem at hand but empowers you to move forward with confidence.

Secat’s Approach: From Mystery to Meaningful Answers

Every investigation starts with your product’s unique story—its composition, how it’s used, and its full-service history. We tailor every analysis with precision.

Our goal? To transform uncertainty into clarity, so you can make informed decisions and avoid surprises.

What Secat Investigates

Investigation Examples

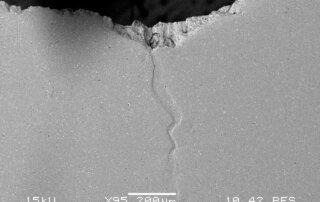

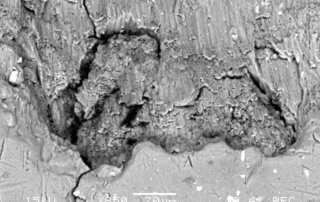

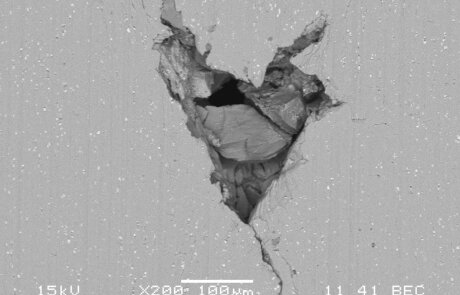

Defects from casting or rolling often lead to pinholes. Secat pinpoints the source using metallographic and chemical tools.

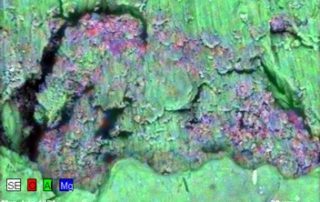

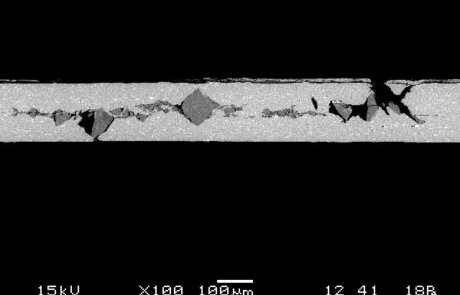

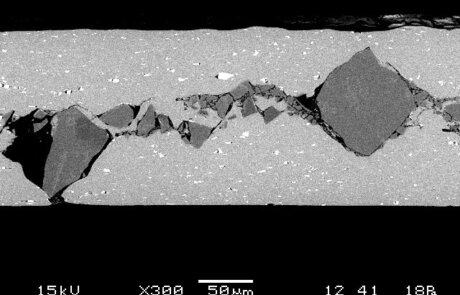

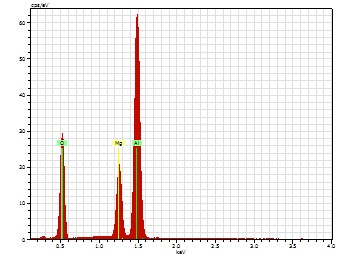

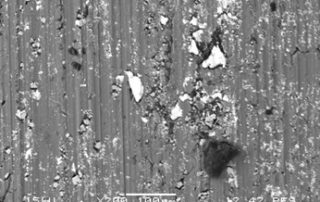

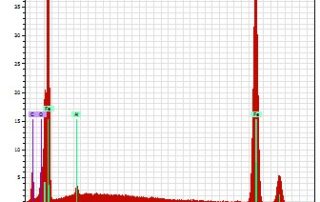

Inclusions from foreign materials like steel chips can compromise sheet quality. We help confirm the source and recommend preventive solutions.