Customer Focus: Secat has the capability to provide modeling of both the aluminum product and the process by which it is made. The modeling capabilities at Secat rely on industry proven methods such as the finite element method (FEM), computational fluid dynamics (CFD), and the CALPHAD method to understand, compare, and predict changes within the product or process for improved results.

The advantage in modeling is in the ability to observe the product or process in a way that is physically not possible. Customers have utilized Secat’s modeling expertise to validate improvements to melting furnace burners, changes to furnace layouts for improved molten flow, and to better understand ingot casting parameters on ingot cracking to name a few. Customers have also been able to pose hypothetical changes that help to steer the development process in an efficient way prior to implementing changes. Below are the modeling packages available at Secat.

ABAQUS

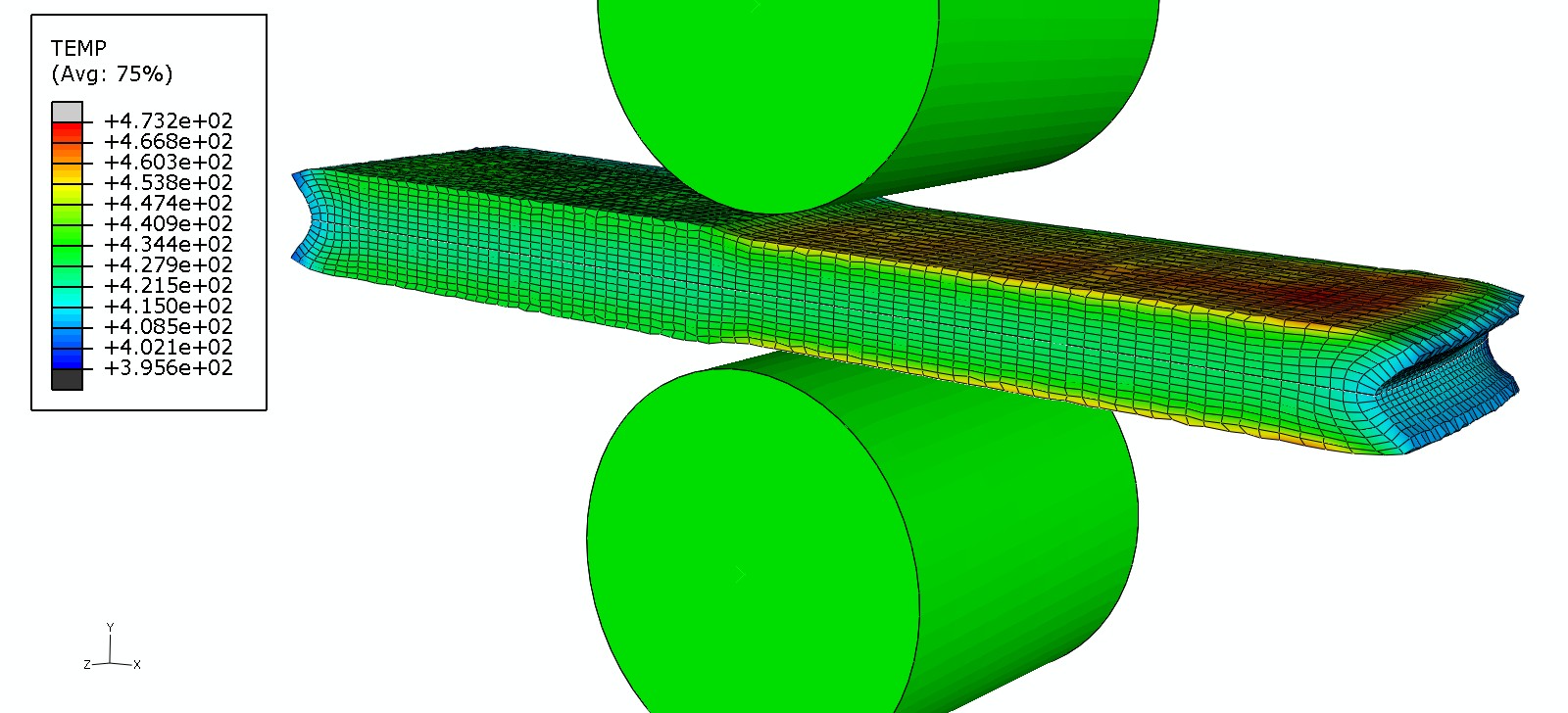

ABAQUS is a robust FEM simulation environment for modeling of static and dynamic thermo-mechanical processes. ABAQUS has been utilized in modeling of rolling, extrusion, impact forming, deep drawing, and many other areas. In addition, the design of ABAQUS allows for extension into other non-traditional areas of FEM such as crack modeling, coupling to microstructure models, and crystal plasticity finite element methods.

Figure 1 below shows an ingot rolling model using the ABAQUS software.

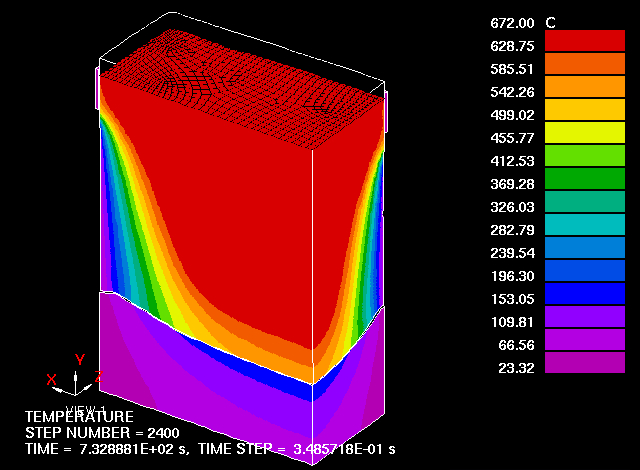

ProCAST

ProCAST is a FEM software tailored toward the field of casting and molten metal flow with specialized features for modeling of sand casting, die casting, centrifugal casting, investment casting, and ingot casting. The ProCAST software has been successfully utilized to study molten metal flow in multi chambered furnace designs, understanding of circulating flows in round hearth furnaces with and without the use of external pumping action, and understanding the parameters affecting ingot cracking in DC casting. ProCAST can also be utilized in the area of microstructure and defect prediction. The CAFE extension in ProCAST is a cellular automaton finite element (CAFE) procedure for the prediction of grain structure in ingot casting. ProCAST also has several utilities to predict areas of porosity and inclusion accumulation points within a casting to help with developing better gating and runner design.

Star CCM+

Star CCM+ is a CFD Multiphysics modeling package. The package is well suited towards modeling of furnaces, their burners, combustion, and gas flow. The Star CCM+ software has successfully been used at Secat to model several round top furnaces along with accurately modeling proposed upgrades to newer generation burners. Modeling of the burner configuration, the combustion efficiency, and the heat transfer in a loaded environment and flat bath situation has been instrumental in not only prediction but also understanding negative situations in hypothesis testing of current and proposed impingement angles and its effect on the melt.

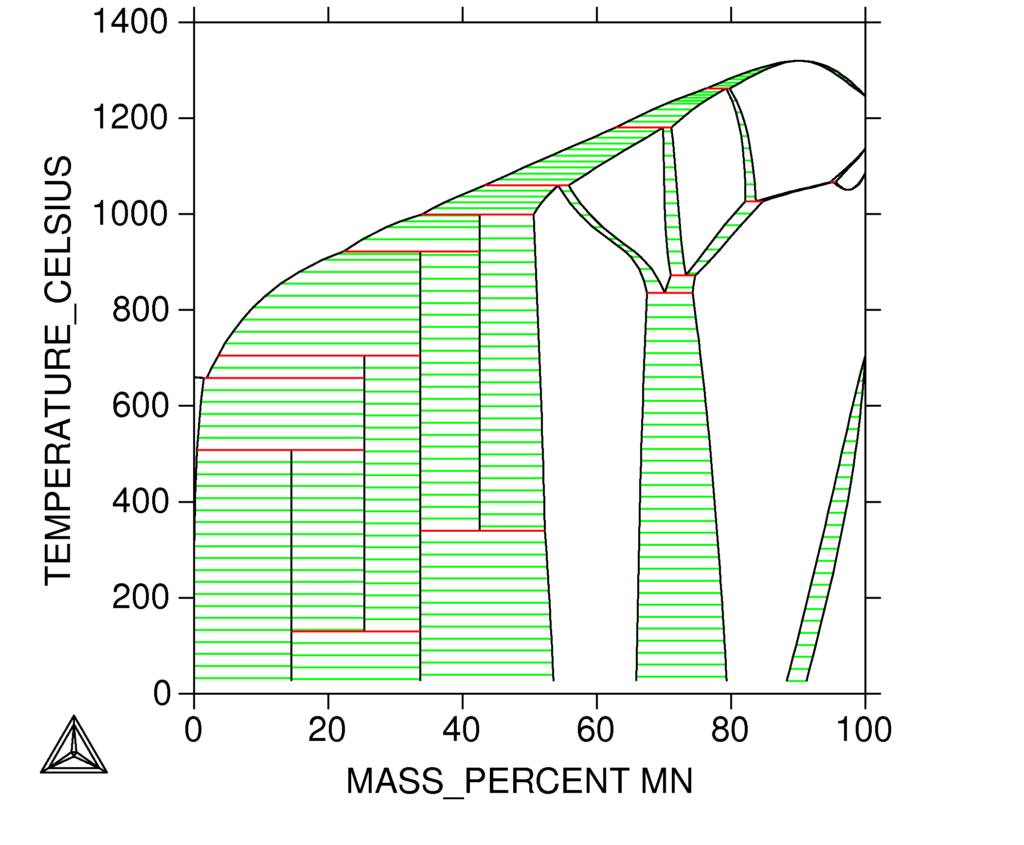

Thermo–Calc and Dictra

Thermo-Calc is a thermodynamics software designed for use primarily in alloy development and in trouble shooting through alloying issues. It is an equilibrium software with an aluminum database covering the vast majority of stable and meta-stable phases. Non-equilibrium solidification can be accounted for through the use of the Scheil-Gulliver feature of the software. Combined with differential scanning calorimetry (DSC), Thermo-Calc can be used to design heat treatments to achieve desired phases and their amounts.

JMatPro

JMatPro is a powerful tool for understanding the physical properties of alloys. JMatPro can be used to predict mechanical properties, phase fractions, dendrite size with cooling curves along with many other physical properties for a given chemistry such as conductivity, density, specific heat, etc. JMatPro also has several modules for designing homogenization treatments and ageing treatments for aluminum alloys with an ability to predict non-stable phases.