Validating Performance, Every Time

Every aluminum component tells a story long before it leaves the foundry. From aerospace engines enduring extreme temperatures and stress, to automotive parts facing repeated cycling loads, the forces a material experiences define its performance. Mechanical testing uncovers how metals will perform in the real world—confirming safety, proving durability, and demonstrating consistency. At Secat, we bring expertise, precision, and advanced equipment to translate these tests into actionable insights.

Certified Expertise You Can Rely On

Our lab is ISO 17025 and NADCAP-accredited, meaning your testing is backed by a system built for traceability, repeatability, and uncompromising quality. From material verification to product qualification, we meet recognized international standards so you can move forward with confidence.

Process That Works With Yours

We don’t just run tests—we work alongside you to verify, refine, and strengthen your processes. Whether you’re troubleshooting a failure, validating a design, or scaling production, our team adapts to meet your needs, integrating our expertise seamlessly into your workflow.

From Simple Tests to Complex Simulations

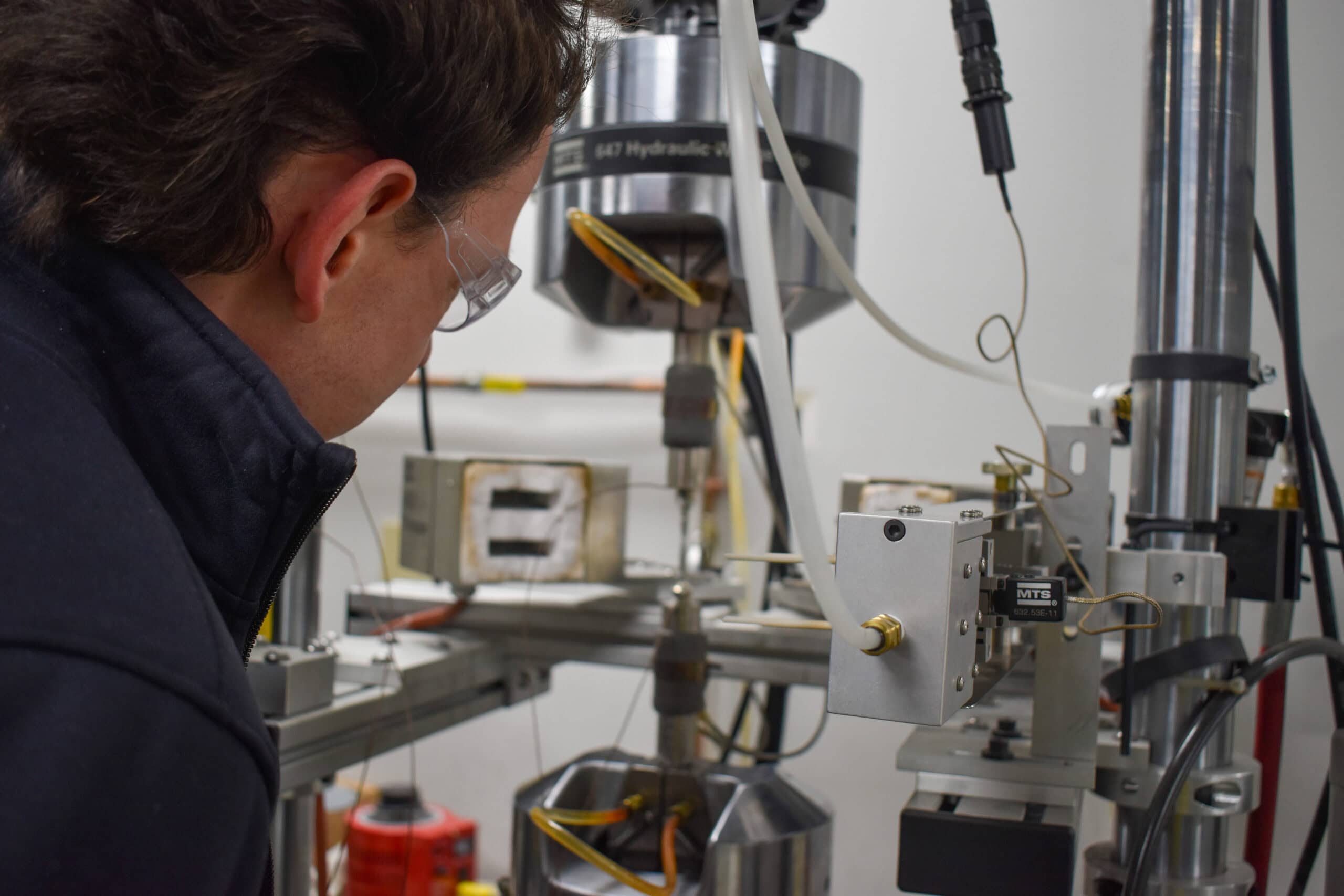

From straightforward tension and compression to advanced fatigue and fracture protocols, we’re equipped to handle it all.

Mechanical Testing Capabilities

At Secat, mechanical testing is performed using a robust lineup of advanced equipment, enabling both rapid and same-day analysis.

QUICK RESPONSE & CLEAR PROPOSAL

Submit a request, and within 24 hours, an expert engineer will respond. We’ll gather any necessary details and provide a clear quote and timeline.

DEDICATED EXPERT & INSIGHTFUL ANALYSIS

We don’t just test—we interpret. Our findings come with expert insights, practical recommendations, and the opportunity for follow-up discussions to support clarity and implementation.

COLLABORATIVE APPROACH

Your project is assigned to a dedicated expert who serves as your main point of contact and oversees it from start to finish. We operate as an extension of your team, providing seamless communication and shared goals.

Used to evaluate mechanical performance at high temperatures.

Used to evaluate mechanical performance at high temperatures.