From Concept to Launch —

Smarter Alloy & Process Development

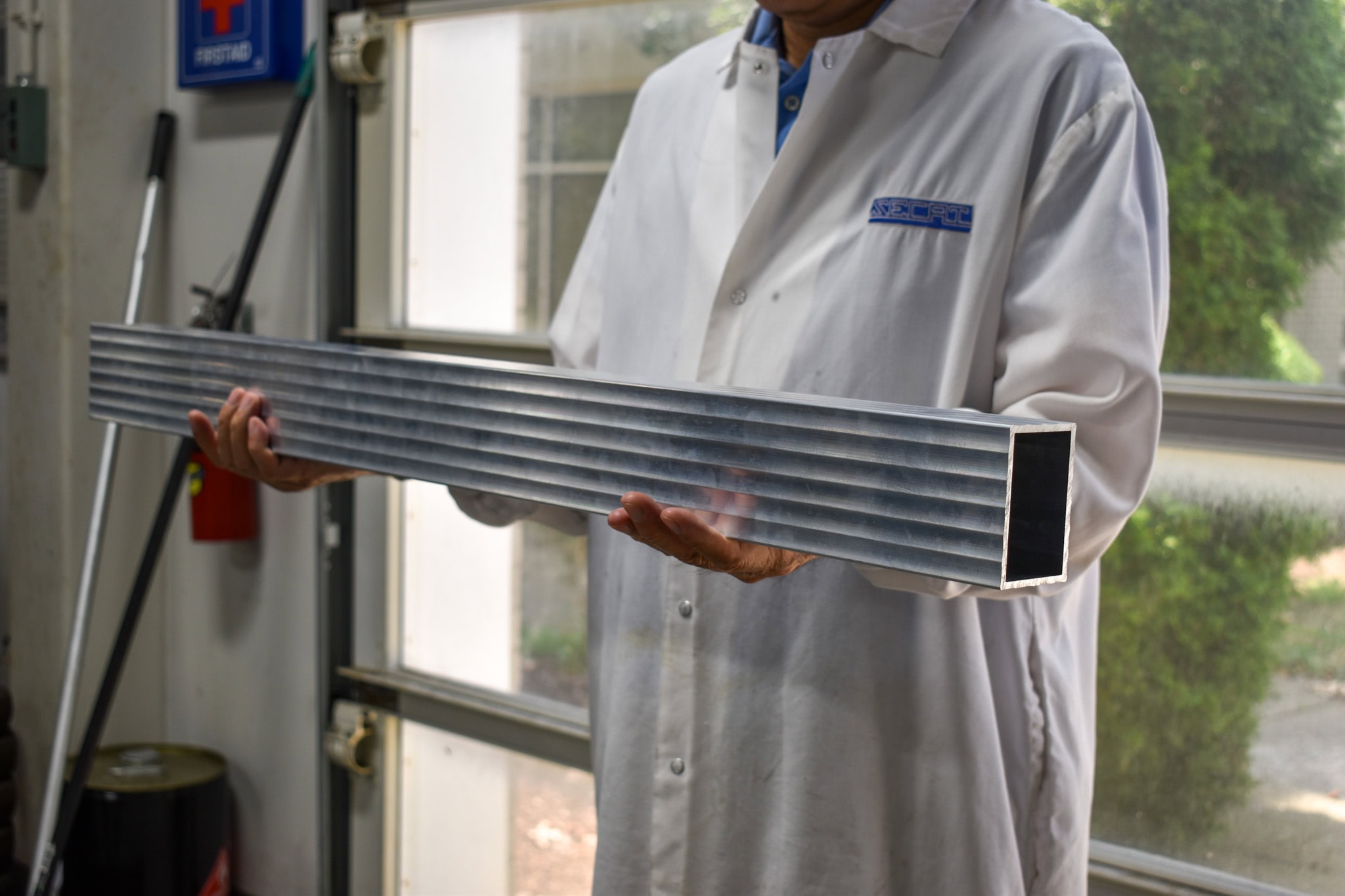

At Secat, we help manufacturers, researchers, and product developers turn ideas into reliable, high-performing aluminum products. Our hands-on alloy and process development services provide the insights, testing, and expertise you need to optimize alloys, forming methods, and small-scale production before committing to full-scale manufacturing.

Whether you’re developing a new alloy, refining a forming process, or testing small castings, we help you reduce risk, accelerate development, and improve product performance.

Why Alloy & Process Development with Secat Matters:

Typical Applications

Why Secat?

Our development isn’t just theoretical—it’s built on decades of aluminum industry experience. We integrate physical data, process knowledge, and advanced simulation tools to give you clear, actionable results. Whether you’re launching a new product or improving a production line, our goal is the same: to help you succeed faster, smarter, and with less waste.

Contact Us Today