|

|

In this issue… Click to jump to article

|

Secat News

Secat Website Has a New Look

If you haven’t visited our website www.secat.net recently, it’s time to stop by the site to check out our redesign. The site has a new look, more information than ever before and a new ease of navigation that will put information in your hands – on your computer screen or mobile device – efficiently and quickly! Stop by soon, and let us know what you think!

#WeLoveAluminum

Aluminum: Wrapped Up – Recap of February Class

Secat, Inc. held another session of Aluminum Wrapped Up: A Basic Understanding of Aluminum, at their facility in Lexington on February 8th. The class was well attended and several of the participants had comments to share about the experience.

“This really pulled it together – all the information was very good. I really liked taking the tour as well.” Lisa McCuiston – Analytical Lab Technician, Logan Aluminum

“I really enjoyed the class – there was information that directly related to a problem we’ve experienced – it gave me some good insight. I can take this back and use the information.”

Zach Knuckles – Coating Lab Technician, Logan Aluminum

“I liked getting the in-depth background, the basic detail on the heat treating, the alloys, the major contributors to make the final product, nomenclature and the different applications. It was a very good overview.” Stephanie Pyzola – Product Support, Logan Aluminum

Make plans now to attend the next session of Aluminum Wrapped up to be held June 28, 2017 in Lexington. SPACE IS LIMITED! Use this link for more information and to register.

#WeWantYouToLoveAluminumToo

Anniversaries

Dr. Chenghe Xiao celebrated 15 years of service in October 2016.

Todd Boggess celebrated 15 years of service in December 2016.

Shridas Ningileri celebrated 15 years of service in January 2017.

CONGRATULATIONS – KEEP UP THE GOOD WORK!

For more information, please contact Todd Boggess at tboggess@secat.net or (859) 514-4989.

|

Secat Makes a Difference

Secat and the Center for Aluminum Technology (CAT) will participate in the University of Kentucky’s Engineers Day on Feb 25, 2017

Engineers Day (or E-Day), which comes at the end of Engineers Week, is a celebration of everything engineering has to offer. From building bridges to discovering new medications to writing the software that powers our cell phones, engineers and computer scientists do the things that make our 21st-century world work. This year E-Day was sponsored by a coalition of more than 100 professional societies, major corporations and government agencies dedicated to promoting math.

Engineers Day is perfect for school-aged children from elementary all the way through high school; especially those interested in learning more about the exciting things engineers and computer scientists do. There are many things to amaze, inform and delight you at the UK College of Engineering. Even parents and teachers will be entertained. There are all kinds of things to see and do at E-Day. You’ll be able to explore many of our research and computer labs to see what our students do. Approximately 150 demonstrations, exhibits and contests hosted by UK Students and Departments, government organizations and industry will be there this year.

Secat & the Center for Aluminum Technology (CAT) will have its own booth in the engineering building on the UK campus and the topic is “How Aluminum Products Are Made”. A wide range of aluminum products will be presented at the booth and manufacturing demonstration videos will be shown. Visitors will be able to get a close look at how commonly used aluminum products are made including soda cans, aluminum foil, fry pans, etc. Our employees will be present to answer questions related to aluminum.

For more information, please contact Todd Boggess at tboggess@secat.net or (859) 514-4989.

#SecatLovesEngineers

|

Featured Capabilities

Brazing of Aluminum Alloys in Space

National Aeronautics and Space Administration (NASA) has selected to fund a four-year research project entitled “Brazing of Aluminum Alloys in Space”. The project is in response to the NASA Research Announcement “Research Opportunities in Materials Science – MaterialsLab, Open Science Campaigns for Experiments on the International Space Station”.

The Principal Investigator of the project is Dusan P. Sekulic, Secat J.G. Morris Aluminum Professor at the College of Engineering, Department on Mechanical Engineering and the Institute of Sustainable Manufacturing at the University of Kentucky, Lexington, KY. The project is aimed at scientific research, both theoretical and experimental, of the brazing process to be executed in a microgravity environment. A significant emphasis of the research objectives is aluminum brazing technology development.

The proposal includes a collaborative participation of the School of Mechanical and Material Engineering, Washington State University, Pullman, WA, as a subcontractor. The overall project, directed by Dr. Sekulic as a Principal Investigator, is structured as an international research endeavor involving, in addition to NASA, the European Space Agency (ESA/BELPOS) and Russian Space Agency (ROSCOSMOS). The NASA funding is US $600,000 for the period between November 2016 and November 2020. The ESA will fund European collaborative partner, KU Leuven, Department of Materials Science, with up to Euro 490,000 and ROSCOSMOS will fund the Russian collaborating institution, Udmurt State University with up to Rubles 3,000,000. The total funding is expected to be around 1.2 Million US Dollars, half of it already appropriated by NASA for the US based research.

The motivation for the proposed research work is rooted within a pragmatic technological advancement needed to resolve critical issues involving current and future endeavors in space exploration, as mandated by NASA’s mission and associated activities. Among these, a resolution and/or mitigation of two outstanding problems are of both short-term and long-term importance. The outer hulls of space vehicles and structures may suffer damage caused by micro-meteorites or orbital debris impact. Thousands of submicron craters form over time but may not cause catastrophic consequences, but occasionally an impact leads to a serious penetration, as indicated by one of the project’s motivation arguments. A brazing method suited for implementation in outer space and/or at the International space station (ISS), intended to mitigate that impact, requires a variety of aluminum research studies. Moreover, the need for facilitating construction in space will be necessary in future space missions. Structural elements, transported to Earth’s orbit and beyond to the Moon and/or Mars must subsequently be joined under extraterrestrial conditions. Joining aluminum by brazing would be one of the most seriously considered options.

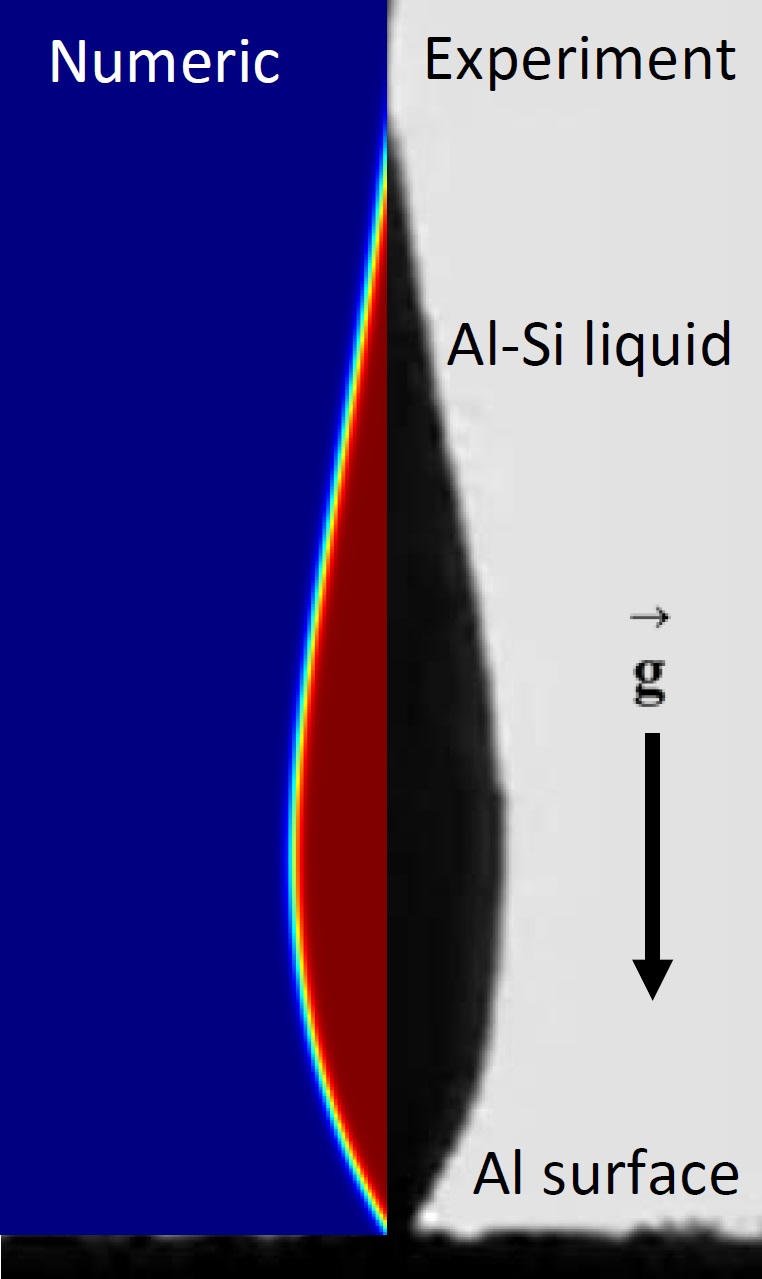

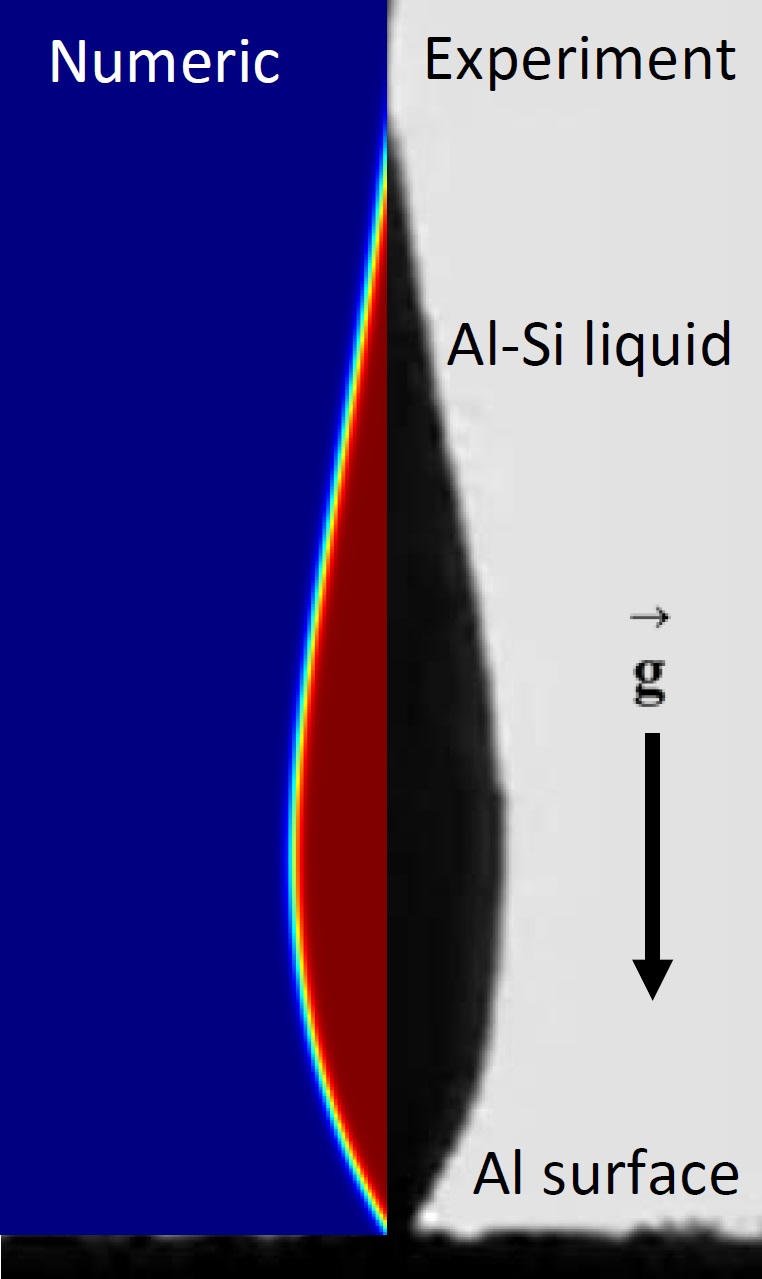

This research program involves controlled atmosphere and vacuum brazing of aluminum to be performed in the Brazing Laboratory of Dr. Sekulic at the University of Kentucky. The phase change cycle of aluminum alloys studied in real time and in situ will include studies of the kinetics of surface tension drivel liquid metal flows, capillary phenomena, melting and solidification of the clad/filler of aluminum alloys in the presence or absence of flux. The terrestrial tests will be complemented with tests on the ISS under microgravity conditions. The experimental work performed under terrestrial and space conditions will be coordinated by the University of Kentucky team. This work will be complemented by the work at UK Leuven, Belgium, by Dr. Jan Fransaer, and Dr. Mikhail Krivilev at the Udmurt State University, Russia. The computational and theoretical modeling program will be conducted by the Co-PI, Sinisa Dj. Mesarovic at the Washington State University Dr. David Seveno, KU Leuven, and Dr. M. Krivilev in Russia. The capillary flow of liquid aluminum alloys is a complex phenomenon and follows equally complex solid state and fluid phase transformations, leading ultimately to solidification and along the way an evolution of microstructure of the joining domain. For example, in the capillary flow phase, the moving boundary and topological discontinuities (breakup and coalescence of domains) have been very difficult computational problems. These problems will be resolved by using phase field modeling.

In addition to an extensive study of the brazing process, and in particular spreading and wetting capillary phenomena, the studies of aluminum alloy filler metal design will be considered. An Al-Si-(KFAl) alloy electrodeposition will be utilized, assisted by Si nanoparticles. Subsequently 3000- and 2000-series Al substrate will be coated with so-developed clad.

All experimental and theoretical/numerical works, under both terrestrial and microgravity conditions, will significantly broaden understanding of joining phenomena involving metals (aluminum in particular) and will advance the technology of aluminum brazing.

Figure B Numerical prediction and an experimental profile of the molten Al-Si initially situated over the horizontal Al2O3 non-wetting substrate, after spreading against gravity over an Al3003 vertical surface.

|

|

Person of Interest

Tom Testwuide, Sr., CEO of Skana Aluminum

Skana Aluminum Company was started seven years ago when Tom Testwuide, Sr. had a vision. Retired ten years after the sale of his company in Sheboygan, Testwuide was eager to “get back in the game” which he did with the purchase of the bankrupt assets of Koenig & Vits (the former Mirro Co. aluminum rolling mill).

The 650,000 square foot-shuttered plant provided an opportunity to apply his experience in commodity processing to “aluminum” and bring to life “a gem of an asset” in Manitowoc, WI. With the financial support of four close friends, all successful in their own way Testwuide embarked on this journey by winning the bid at the bankruptcy auction on April 22, 2010. The only other bidder, a Chinese company wanted to relocate the assets to China.

Throughout Skana’s short history we have invested in our people, process and equipment. Six months into operations Skana received ISO 9001-2008 certification and has consistently passed bi-annual audits and recertification.

Upgrades to equipment electronics, physical structures, and many new equipment installations have all benefited our performance, energy needs, productivity/output and sales development. Skana has pioneered laser-fusing of two aluminum coils producing a larger sized coil to meet our customer demands.

In 2017 Skana will begin its largest capital investment with the installation of three new melting furnaces and a casting pit. This equipment will reduce energy and air emissions and downtime exposure, advance safety and increase casting capacity. This project over the next three years, will expand the building footprint and replace 55 year old technology with state-of-the-art equipment.

Skana’s management has turned a cost center aluminum mill into a commercially viable, specialty aluminum business. Our mission statement reads, “Making Friends Is Our Mission” and we believe firmly that we have established solid business friendships based on proper execution of our commitments to our customers, employees, vendors, community and investors.

How do you interact with Secat, Inc. and how does the relationship benefit you?

Our team in Manitowoc, WI has many years of experience, but they had not had the opportunity to visit other facilities or interact with outside consultants. Secat and their resources have been very helpful to our operating team in understanding and improving our quality throughout our operations. We had the opportunity to have Secat visit our mill and gave us an exclusive Aluminum Wrapped Up training for 30 of our employees.

What excites you about the future of Aluminum and why?

The demand of the U.S. auto industry is game changing. The “green values” that aluminum brings to many products and its infinite recycling capabilities, make it an amazing product with long-term benefits for the environment and consumers worldwide.

Tell us something about yourself (outside of the industry) that people may not know.

Wendy and I have four adult children and ten grandchildren. We have lived in Sarasota, FL the past 14 plus years, retaining a summer “golf cottage” in Sheboygan WI, my hometown. My family and I have had a lifetime love for the game of golf. I have played since I was 8 years old. Golf teaches one, strong etiquette, individualism, self-policing, and much humility.

Coming out of “semi-retirement” 7 years ago to lead the “rebirth” of these aluminum operations in Manitowoc, WI and Clarksburg, WV have kept me young and energized. All at Skana truly believe we are doing our part to “make America great again!!”

#TomLovesAluminum

|

|

|

|

|