While on a weekend getaway in Kitty Hawk, North Carolina, we found an artist who uses aluminum in some of her art – what a find!

Multi-media artist Julie Moye works in many mediums, including oils, watercolors, mosaic with tiles and glass, pottery, concrete and found objects. Julie works in the medium of the day in order to vent her creativity. Much of her work is on display at KDH Cooperative gallery and studios, a business she envisioned and opened in May of 2001. Other large scale works such as glass and tile murals and tile installations are on view around the Outer Banks in public areas as well as in private homes. With beginnings in the art world as an educator, Julie worked as elementary, middle and then college art teacher in Arizona and in North Carolina’s Outer Banks. She still finds time to teach a variety of children’s and adult art

classes at the gallery. “Teaching is just one way I find inspiration for my own creativity.” Julie lives in Kitty Hawk with her husband, grandson, and two dogs.

We asked Julie some questions about her work:

When did you start using recycled aluminum?

Probably four years ago after I was part of a tin collage workshop and started using some aluminum mixed into the work, all nailed onto wood.

What pieces do you make with recycled aluminum?

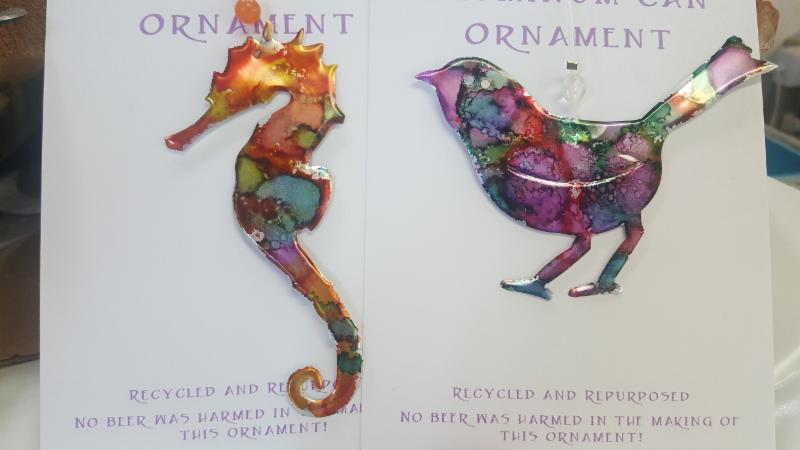

I make collages with aluminum, tin, and paint. I also make a series of aluminum can ornaments and cards. I embellish them with alcohol ink which really gleams on the aluminum surface.

What is your process?

I use recycled aluminum cans. I cut them apart, flatten them and then cut out my designs by hand or with the use of a small die cutter or punches. I then embellish them with alcohol inks, beads and other materials that inspire me.

What inspires you?

Humor and puns inspire me in every way, but sometimes the materials themselves inspire me to find a use for them in a new and creative way. That is the most fun I have in my studio, finding some cast off object and making it into an art object to be loved or laughed at.

One fairly large piece including aluminum was titled Can-tail Mermaid which was purchased by a local physician’s office. That piece incorporated aluminum cans, featuring the original art of the can.

How can people purchase your work?

I sell most of my work through our gallery KDH Cooperative Gallery & Studios here on the Outer Banks of NC. The website iswww.kdhcooperative.com. I love to hear from patrons and will take commissions occasionally. I sell some small works such as cards and some clay work through some regional galleries and as far away as New Jersey.