Understand Your Materials –

See what’s happening beneath the surface

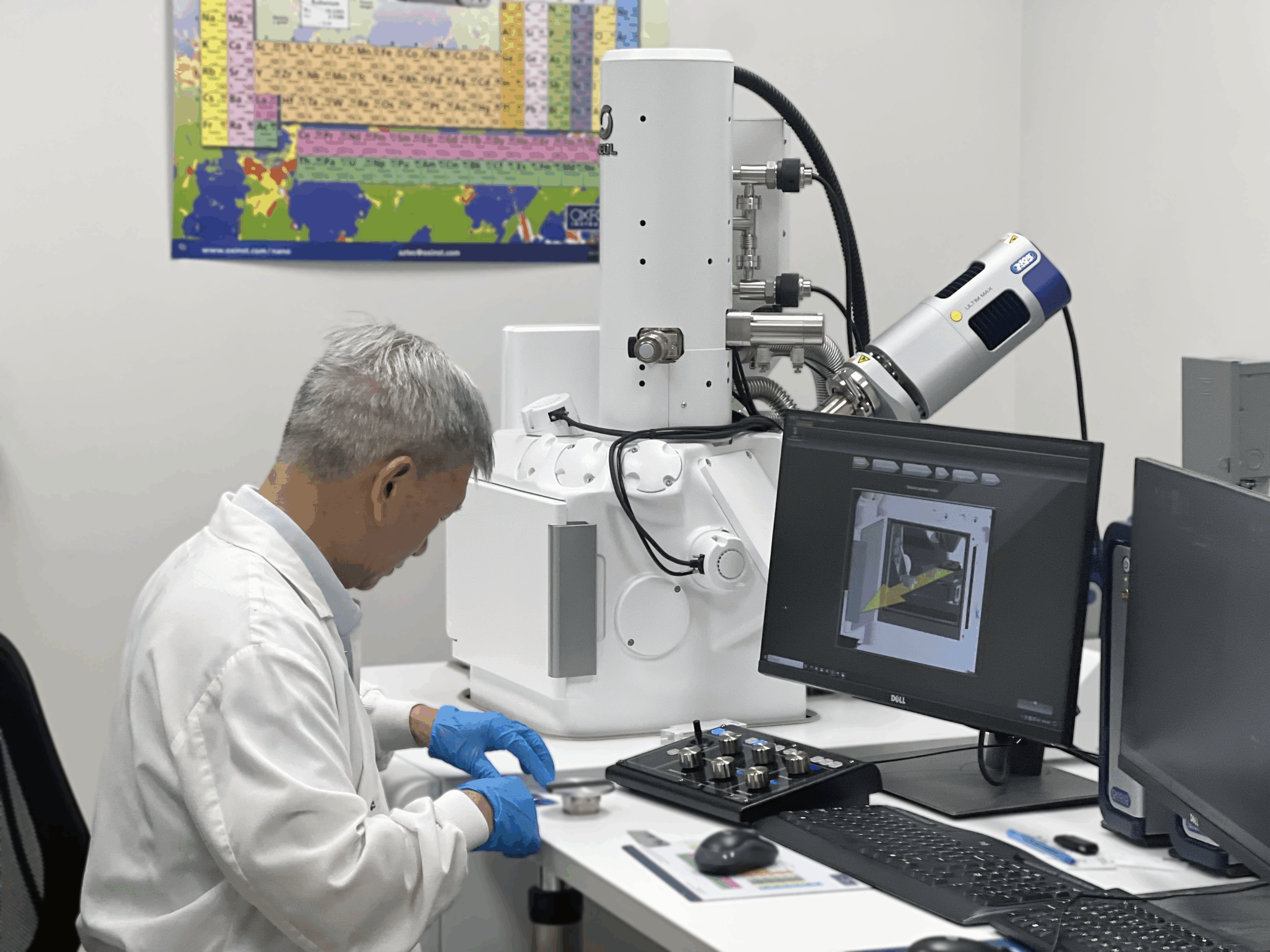

At Secat, we give you a complete picture of your materials — from microstructure to performance. Our hands-on characterization services provide actionable insights that help you optimize alloys, improve processes, and develop high-performing products.

Our Lexington laboratory offers state-of-the-art facilities for materials testing and development, giving you the tools to evaluate, refine, and advance your products with confidence.

Why Characterization Matters

Every piece of metal tells a story. Through advanced characterization techniques, Secat helps you uncover what’s happening beneath the surface — so you can make informed decisions, solve production challenges, and develop better materials.

Benefits of Materials Characterization Testing:

-

Evaluate quality and consistency of materials

-

Detect and understand defects or failures

-

Support process improvement and R&D

-

Validate supplier materials and heat treatments

-

Document compliance with standards or specs

Materials Characterization Services

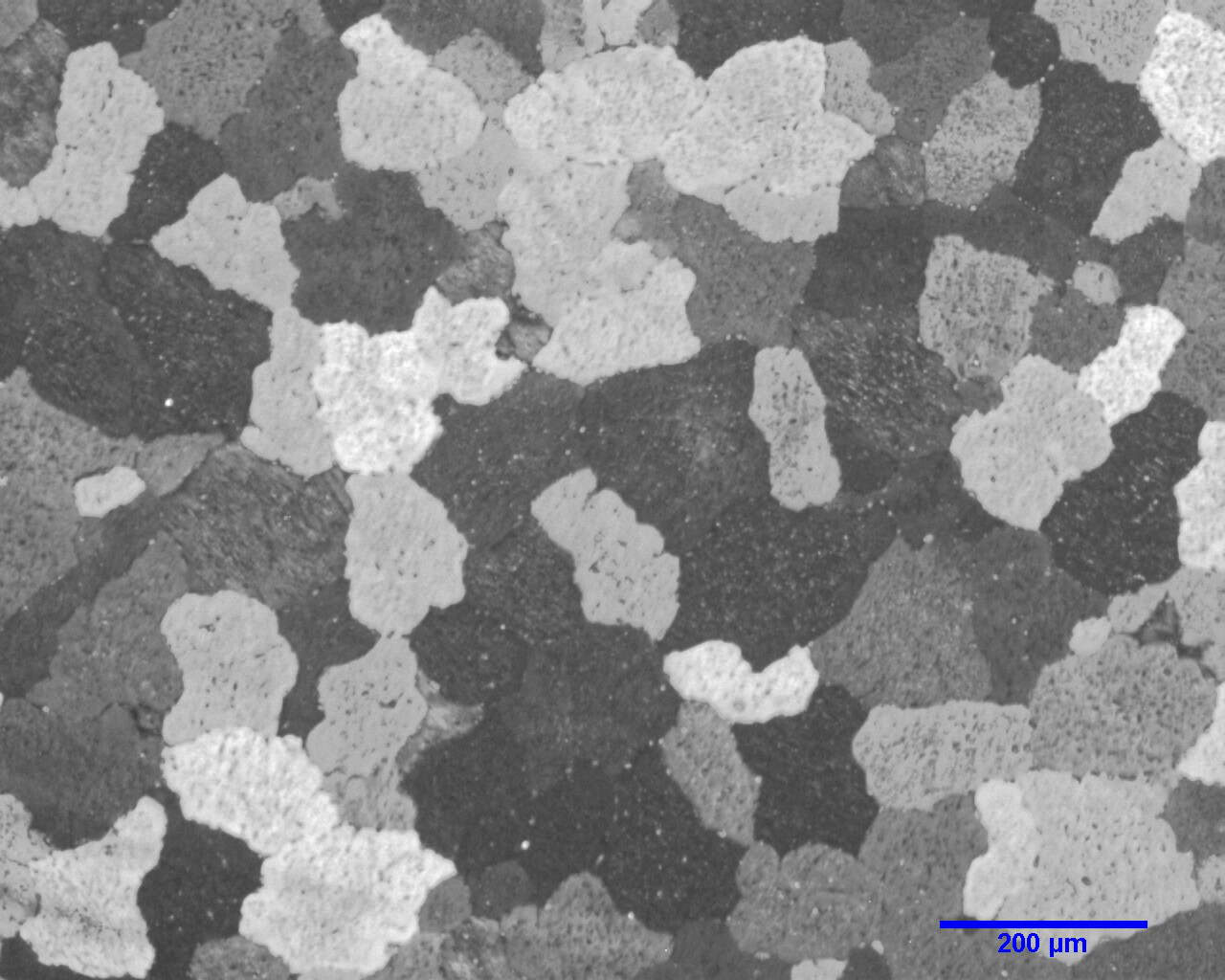

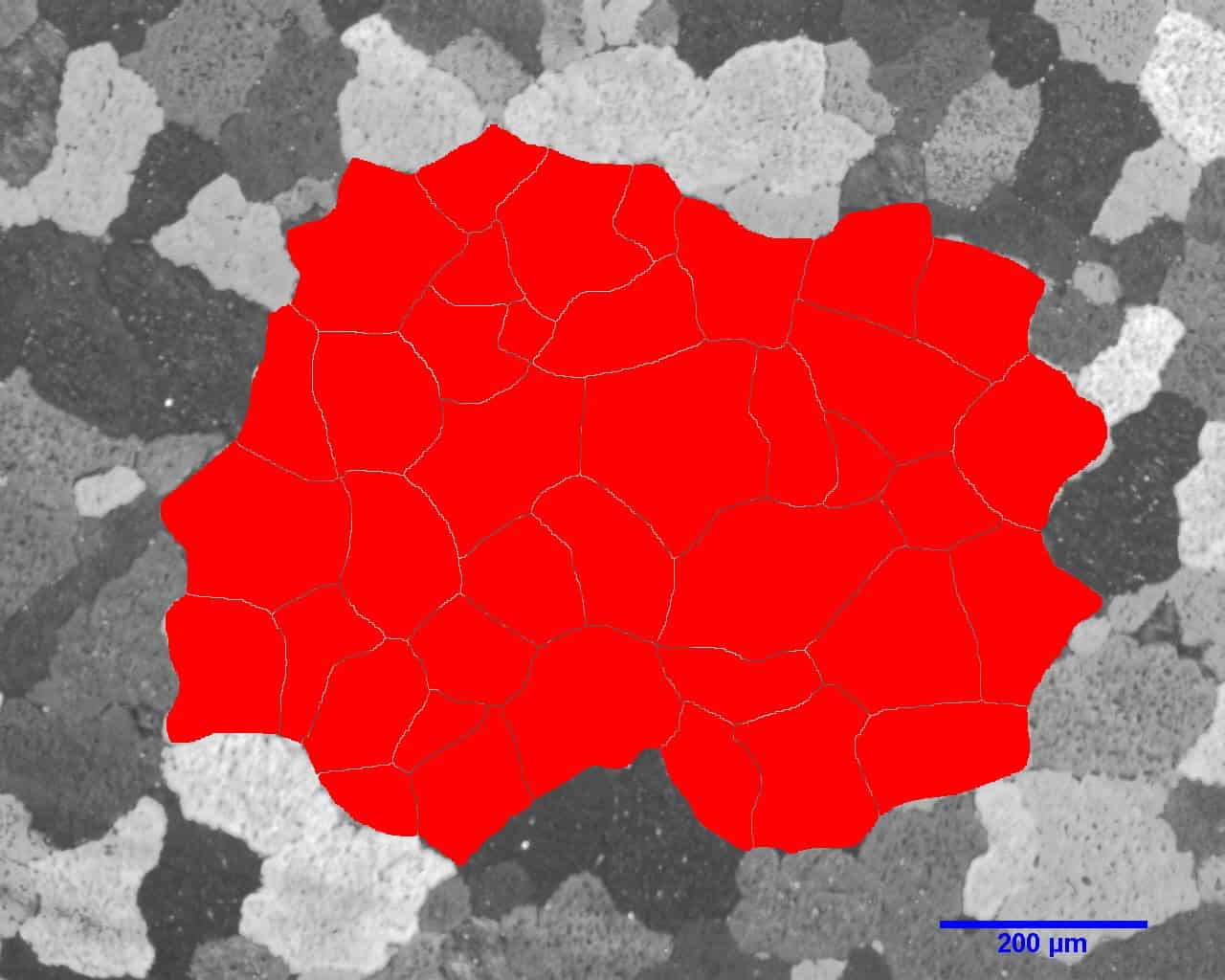

Microstructural Analysis

-

Optical Microscopy: Examine grain structure, phase distribution, and surface features.

-

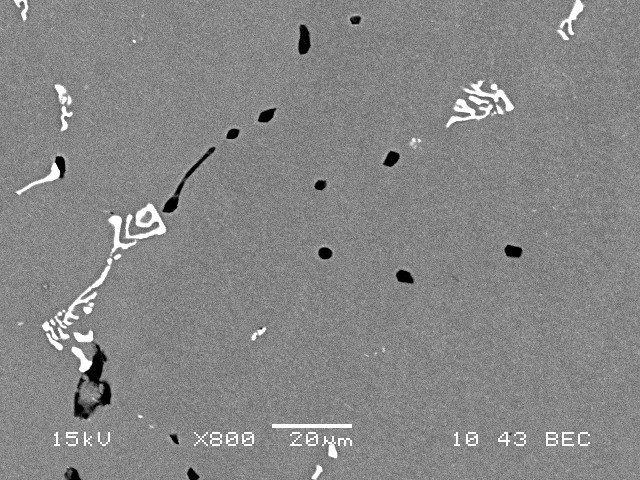

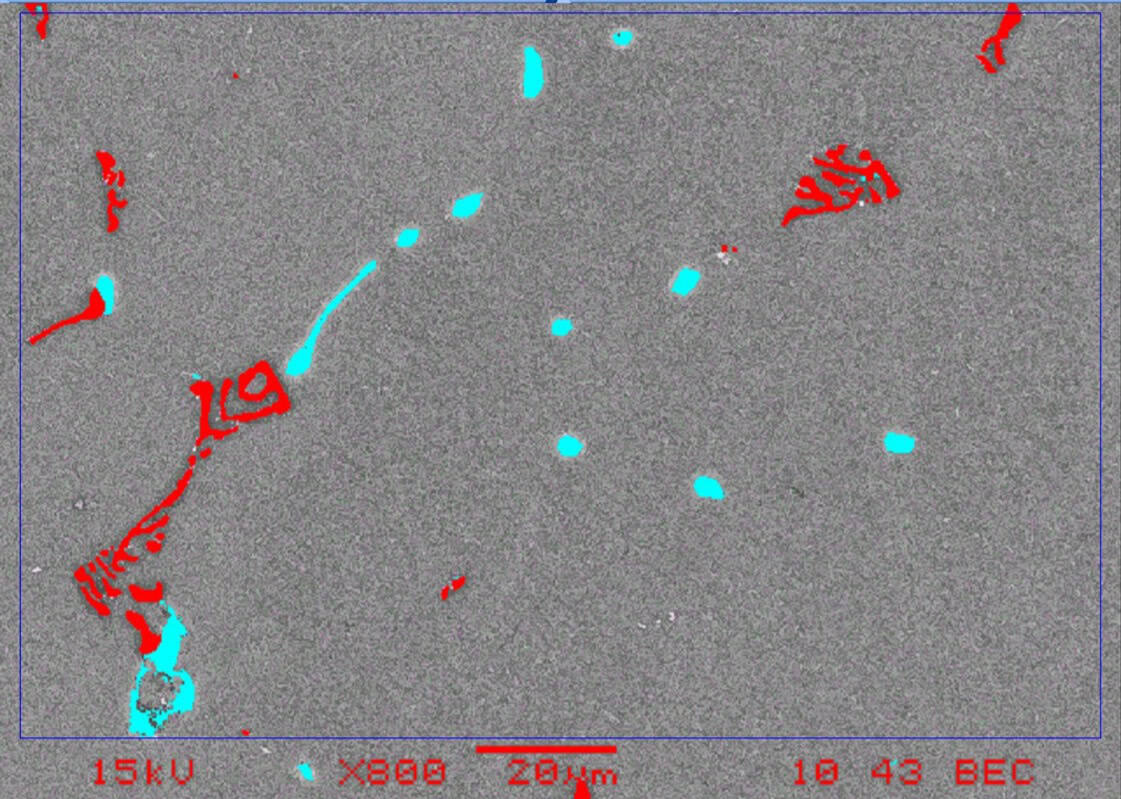

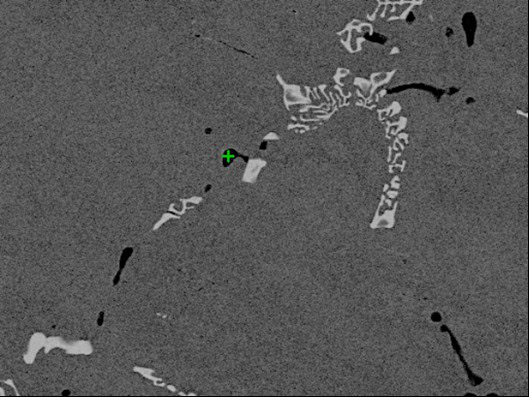

Scanning Electron Microscopy (SEM): High-resolution imaging for detailed surface morphology and elemental analysis.

-

Transmission Electron Microscopy (TEM): Nanoscale examination of internal structures and interfaces.

Elemental and Phase Composition

-

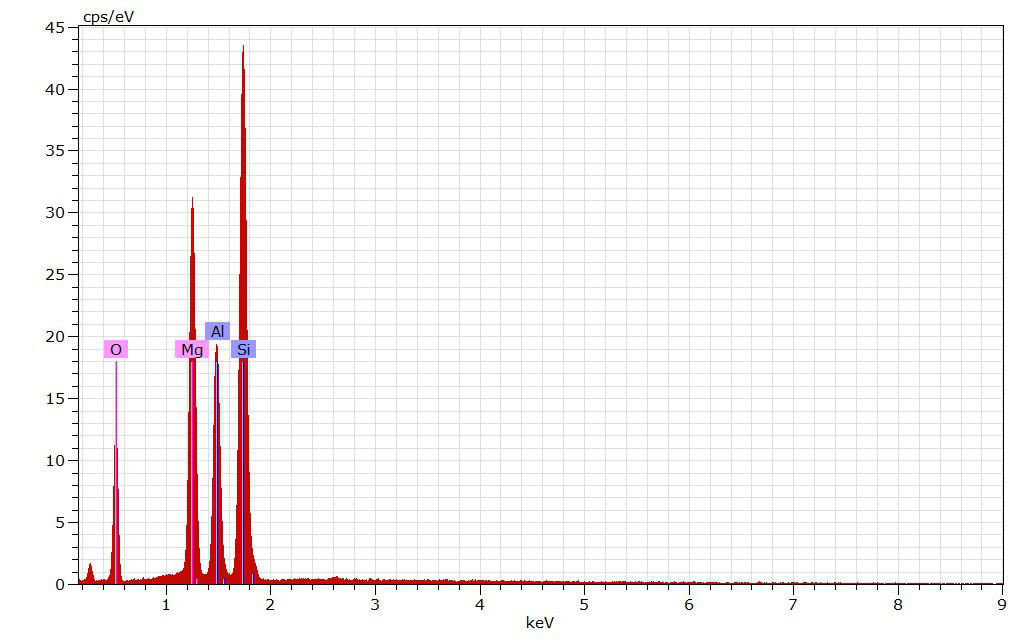

Energy Dispersive X-ray Spectroscopy (EDS): Elemental mapping and quantification.

-

X-ray Diffraction (XRD): Phase identification and crystallographic analysis.

-

X-ray Photoelectron Spectroscopy (XPS): Surface chemical state and composition profiling.

Thermal and Surface Analysis

-

Differential Scanning Calorimetry (DSC): Thermal transitions and stability.

-

Thermogravimetric Analysis (TGA): Decomposition and thermal stability.

Weld & Joint Evaluation

-

Analyze weld quality, interfaces, and defects to ensure integrity and performance in fabricated assemblies.

Investigation Examples

Grain Size Evaluation

Particle Size Evaluation

Particle Size Evaluation

SEM/EDS