Molten Metal for Stronger Castings and Reliable Performance

The quality of your molten metal is the foundation for every product. When a melt isn’t clean, consistent, or well-controlled, the result can be defects, compromised reliability, and costly issues down the line.

Your process, our expertise—right where you need it.

At Secat, we understand that molten metal quality isn’t just another step in production—it’s the heartbeat of your entire casting operation. Whether you’re producing billets, ingots, or shape-cast parts, the integrity of your melt sets the tone for everything downstream.

Flexible Service Models Tailored to You

We meet you where you are—offering two ways to partner with Secat depending on your process needs, timelines, and resources.

Onsite Expertise

- Direct Collaboration: Our analysts go straight to the source at your facility.

- Immediate Feedback: Real-time testing and evaluation within your process environment.

- Practical Guidance: Tailored recommendations based on live data.

- Confidence in Control: Validate melt practices before issues reach downstream casting.

Ideal for billet, ingot, and shape casting operations needing onsite expert testing and support.

Sample Submission

- Controlled Testing: Ship filters, solid samples, or dross to Secat’s lab.

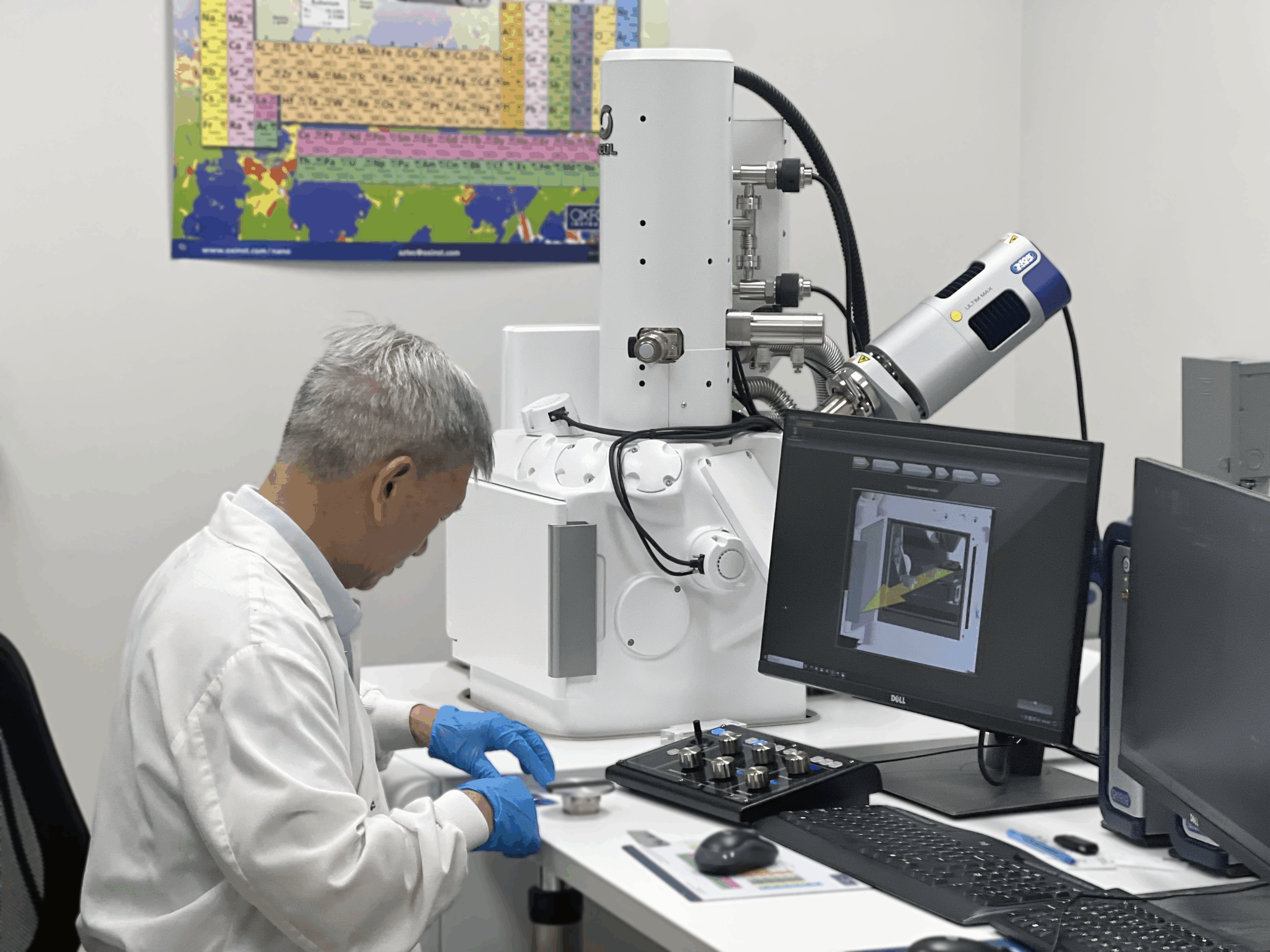

- Comprehensive Analysis: Access advanced equipment and experienced metallurgists for detailed evaluation.

- Formal Reporting: Receive in-depth documentation and insights.

- Independent Benchmarking: Compare results against your own quality checks or across multiple facilities.

Best for extended studies, verification or when onsite isn’t practical.

Achieving Molten Metal Excellence with Secat

Why Molten Metal Quality Matters

From automotive parts to aerospace components, packaging, and construction materials, the metal you pour sets the stage for every downstream process. Issues like inclusions, hydrogen porosity, oxide bifilms, or off-spec chemistry typically originate in melt handling and control. These defects can compromise mechanical properties, reduce reliability, and increase scrap.

Secat’s mission is to provide data-driven insight so you can identify these issues early, optimize your melt practices, and achieve cleaner, more consistent results. Using advanced techniques such as PoDFA for inclusion characterization, Alscan for hydrogen measurement, OES for chemistry verification, and XRD/SEM for dross analysis, we help ensure your billets, ingots, and shape-cast products meet the highest quality and performance standards.

PoDFA (Porous Disk Filtration Analysis)

Captures inclusions from liquid aluminum on a filter for microscopic evaluation, either onsite or in our lab.

PoDFA is a proven method for evaluating the cleanliness of molten aluminum by capturing non-metallic inclusions on a porous filter. This analysis provides insight into the types, quantities, and sources of inclusions that can affect casting quality, porosity, and mechanical performance.

Onsite Retrieval: Secat analysts can come to your facility to extract PoDFA filters directly from liquid metal. This ensures proper sampling and immediate transfer for evaluation.

Sample Submission: If your team has PoDFA filters already retrieved, you can send them to Secat for detailed laboratory evaluation. Our metallurgists perform microscopic analysis and provide thorough inclusion characterization for process monitoring and quality control.

Cold PoDFA: When the product is already cast—such as billets or other solid forms—samples can be sectioned, remelted, and then analyzed through PoDFA. This approach allows inclusion characterization even after production, making it valuable for quality investigations, audits, or process verification.

By offering multiple pathways to PoDFA, Secat ensures you can access accurate inclusion data whether you need immediate melt evaluation, lab-based analysis, or post-production confirmation.

Hydrogen Measurement

Assessed in liquid metal with Alscan or in solid samples with LECO

Hydrogen dissolved in molten aluminum is a critical concern—particularly in aerospace applications, where even small levels of porosity can compromise mechanical properties and reliability. Accurate measurement of hydrogen content is essential for ensuring melt cleanliness, preventing casting defects, and maintaining product performance.

Onsite (Alscan): Hydrogen in the liquid melt is measured directly at your facility, providing immediate feedback on melt cleanliness and enabling real-time adjustments to your process. This hands-on approach allows our experts to work alongside your team to identify potential issues before they affect production.

Equipment Rental Option

For added flexibility and cost-savings, Secat’s Alscan unit is also available for rental—giving your operation access to advanced measurement technology when and where it’s needed.

Sample Submission (LECO): Solid samples can be sent to Secat’s laboratory for precise hydrogen analysis using LECO instrumentation. This method offers highly accurate, traceable results that help confirm melt quality, troubleshoot recurring porosity problems, and validate process improvements.

By combining these approaches, Secat provides both immediate operational insight and detailed lab-based verification, giving you confidence in your aluminum melts and ensuring consistent, defect-free castings.

Optical Emission Spectroscopy (OES)

Verifies melt chemistry, supports round-robin programs, and serves as a backup to cast house analysis.

Benefit: OES is a critical tool for ensuring that aluminum melts meet specification and maintain consistent chemistry. By analyzing the elemental composition of the melt, OES verifies that alloys are within tolerance, helping prevent off-spec metal from entering production. Beyond basic chemistry checks, it can be used to support round-robin programs to benchmark accuracy, providing a reliable backup to cast house measurements, and aiding in troubleshooting process issues. With OES data, producers can make informed decisions about alloy additions, blending strategies, and quality control, ensuring stronger, more reliable castings every time.

Scrap Remelting

Evaluates chemistry and recovery during remelting to optimize yield and melt quality.

Benefit: Scrap isn’t just waste—it’s valuable feedstock, and its chemistry and recovery directly influence both yield and final melt quality. For scrap suppliers, analysis verifies material integrity and provides confidence in the value of what’s being sold. For buyers and casthouses, scrap evaluation ensures consistency, reduces risk of unwanted elements, and supports smarter blending strategies. Our studies help both sides make informed decisions, improve recovery, and maximize long-term efficiency.

Dross Analysis (XRD/SEM)

Characterizes dross phases and inclusions to improve recovery and reduce waste.

Benefit: Dross is an unavoidable byproduct of aluminum melting, containing both metallic aluminum and oxide phases. Understanding its composition is key to controlling losses, improving recovery, and optimizing recycling strategies.

At Secat, we use Fire Assay to determine the recoverable aluminum content of dross. A small sample is melted with a flux mixture that dissolves the oxides while allowing the molten aluminum to separate. Once solidified, the metallic aluminum is weighed and compared to the starting dross mass, revealing exactly how much aluminum can be recovered.

Combined with advanced microscopy (SEM) and diffraction (XRD), our analysis also identifies salts and oxide phases within the dross. For producers, this insight highlights opportunities to improve recovery and reduce waste. For recyclers and buyers, it provides a clearer picture of dross quality, helping separate valuable metallic content from unwanted oxides. The result is more efficient use of resources, reduced costs, and smarter decision-making across the melt and recycling process.

Why Choose Secat?

We combine industry-leading instrumentation like PODFA and Alscan with decades of metallurgical expertise. Our team works closely with your production staff — onsite or by sample submission in the lab — delivering clear, actionable results and practical recommendations. Together, we help you overcome molten metal challenges quickly and sustainably—improving metal quality, reducing defects, and boosting your operation’s reliability.

Your castings begin in the melt. Let Secat help you make sure it’s the best it can be.

Contact us today to discuss your molten metal quality needs and get solutions you can trust.