Understand Your Alloy Chemistry with Confidence

Secat provides accurate and reliable chemical composition testing for aluminum and aluminum alloys using Optical Emission Spectroscopy (OES). Our in-house Arc/Spark OES capabilities allow us to deliver rapid, precise results for alloy certification, verification, and process control—while maintaining full traceability to industry standards.

We also coordinate outsourced ICP-OES and GDMS testing for ultra-trace or specialized analytical needs, ensuring our customers receive the most comprehensive chemical data available.

Our Capabilities

Arc/Spark Optical Emission Spectroscopy (OES)

Our primary method for quantitative elemental analysis of aluminum and its alloys.

- Standard: ASTM E1251 – Standard Test Method for Analysis of Aluminum and Aluminum Alloys by Spark Atomic Emission Spectrometry

- Applications: Certification, verification, and process control of aluminum alloys

- Advantages:

High precision for bulk composition

Fast turnaround and repeatable accuracy

Ideal for both cast and wrought products - Sample Size: 2.0–2.5 in. diameter × 0.25–0.50 in. thick discs

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

(Outsourced)

Used when trace-level analysis or fluid testing is required.

- Standard: ASTM E3061 – Analysis of Aluminum and Aluminum Alloys by ICP-OES

- Applications: Determining trace elements such as Ca, Na, and K

- Advantages:

Better resolution for low-level elements

Suitable for very small samples (as little as 3 g)

Ideal for oil, fluids, and specialty alloy analysis

Optical Emission Spectroscopy (OES)

Verifies melt chemistry, supports round-robin programs, and serves as a backup to cast house analysis.

Benefit: OES is a critical tool for ensuring that aluminum melts meet specification and maintain consistent chemistry. By analyzing the elemental composition of the melt, OES verifies that alloys are within tolerance, helping prevent off-spec metal from entering production. Beyond basic chemistry checks, it can be used to support round-robin programs to benchmark accuracy, providing a reliable backup to cast house measurements, and aiding in troubleshooting process issues. With OES data, producers can make informed decisions about alloy additions, blending strategies, and quality control, ensuring stronger, more reliable castings every time.

Standards & Quality Assurance

All testing adheres to industry-recognized standards to ensure certification-level reliability:

- ASTM E1251 – OES for Aluminum and Alloys

- ASTM E716 – Sampling and Sample Preparation for OES

- ASTM E29 – Rounding for Test Results

- ASTM E3061 – ICP-OES Analysis

- ASTM F1845 – GDMS for Trace Impurities

Our team calibrates all instruments using certified reference materials. Type standardizations and drift corrections are routinely performed to maintain data integrity.

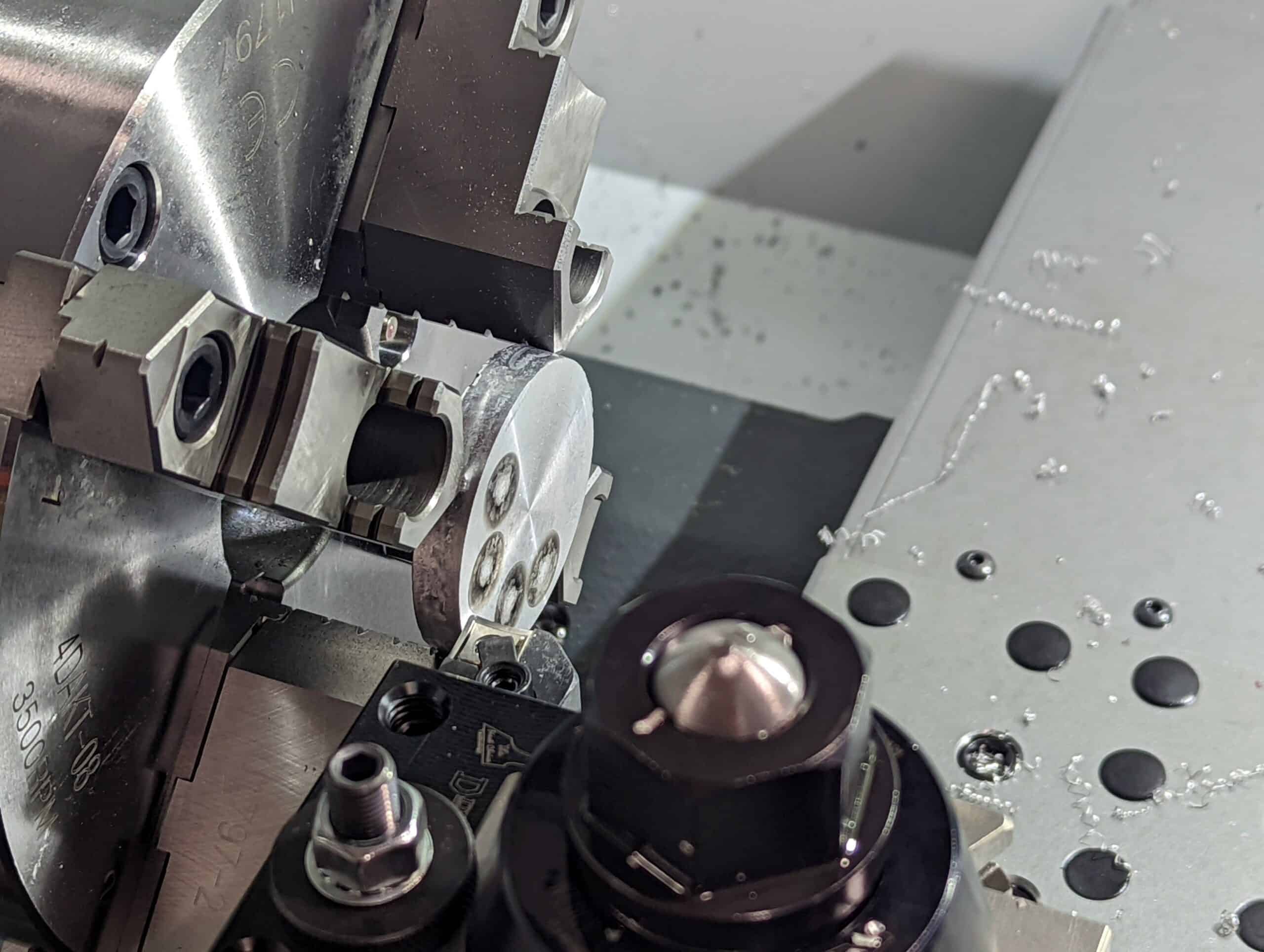

Sample Preparation and Casting Buttons

Proper sample preparation is essential for accurate results.

Secat follows ASTM E716 – Standard Practices for Sampling and Sample Preparation of Aluminum and Aluminum Alloys for Determination of Chemical Composition by OES.

Our process includes:

- Remelting aluminum samples and pouring molten metal into standard disc-shaped molds to create cast “buttons.”

- Pre-heating ladles and molds to minimize shrinkage and contamination.

- Ensuring discs are free of inclusions, cracks, and roughness for best representativeness.

- Machining or turning surfaces to remove oxidation and contamination before analysis.

For thin or fabricated products, samples may be mounted to other masses for accurate readings.

Why Choose Secat?

We combine state-of-the-art OES instrumentation with decades of metallurgical experience to deliver precise, reliable chemical analysis for aluminum and its alloys. Our team works directly with your engineers and production staff—onsite or through sample submission—to ensure your material chemistry meets specification and performance goals.

From alloy verification to trace element detection, we provide clear, actionable data and practical recommendations that help you certify quality, troubleshoot issues, and maintain process control with confidence.

Your materials start with their chemistry.

Let Secat help you ensure it’s right—accurate, certified, and ready for production.

Ready to Get Started?

Whether you need routine certification, alloy verification, or specialized trace element testing, Secat delivers fast, dependable results backed by aluminum-specific expertise.

Contact us today to discuss your chemical analysis needs and get results you can trust.

Learn more about our process working with Secat on your unique or routine project.