Protecting Aluminum and Other Metals from the Elements with Secat

Your product’s story should be one of performance, not premature failure. Let’s protect it together.

Your product’s journey doesn’t end at the factory. Once it’s out in the world, salt, humidity, temperature changes, and contact with other metals can slowly compromise its strength, appearance, and safety.

That’s where Secat comes in. We help manufacturers and engineers understand how aluminum and other metals will perform—before they fail in the field, or after a problem arises. Our testing reveals vulnerabilities, validates protective treatments, and guides smart material choices.

Why Corrosion Testing Matters

Even the most corrosion-resistant metals aren’t invincible. Testing with Secat helps you:

- Spot issues before they become failures.

- Compare alloys and coatings in realistic conditions.

- Meet quality standards and customer requirements.

- Find the root cause of in-service corrosion.

Secat’s Capabilities

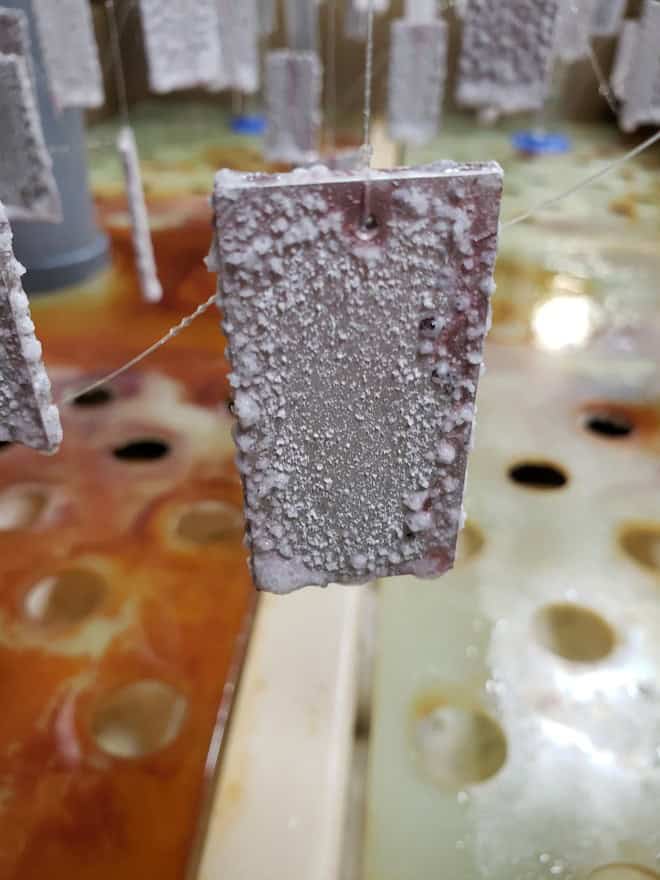

- Salt Spray (ASTM B117) – Simulates marine/industrial exposure.

- Cyclic Corrosion Testing – Wet/dry/salt-fog cycles for real-world stress.

- Galvanic Corrosion Testing – Checks metal-to-metal compatibility.

- Post-Corrosion Analysis – Metallographic, SEM/EDS, and more.

Protect Your Assets.

Prevent Failure. Ensure Longevity.