What is EBSD?

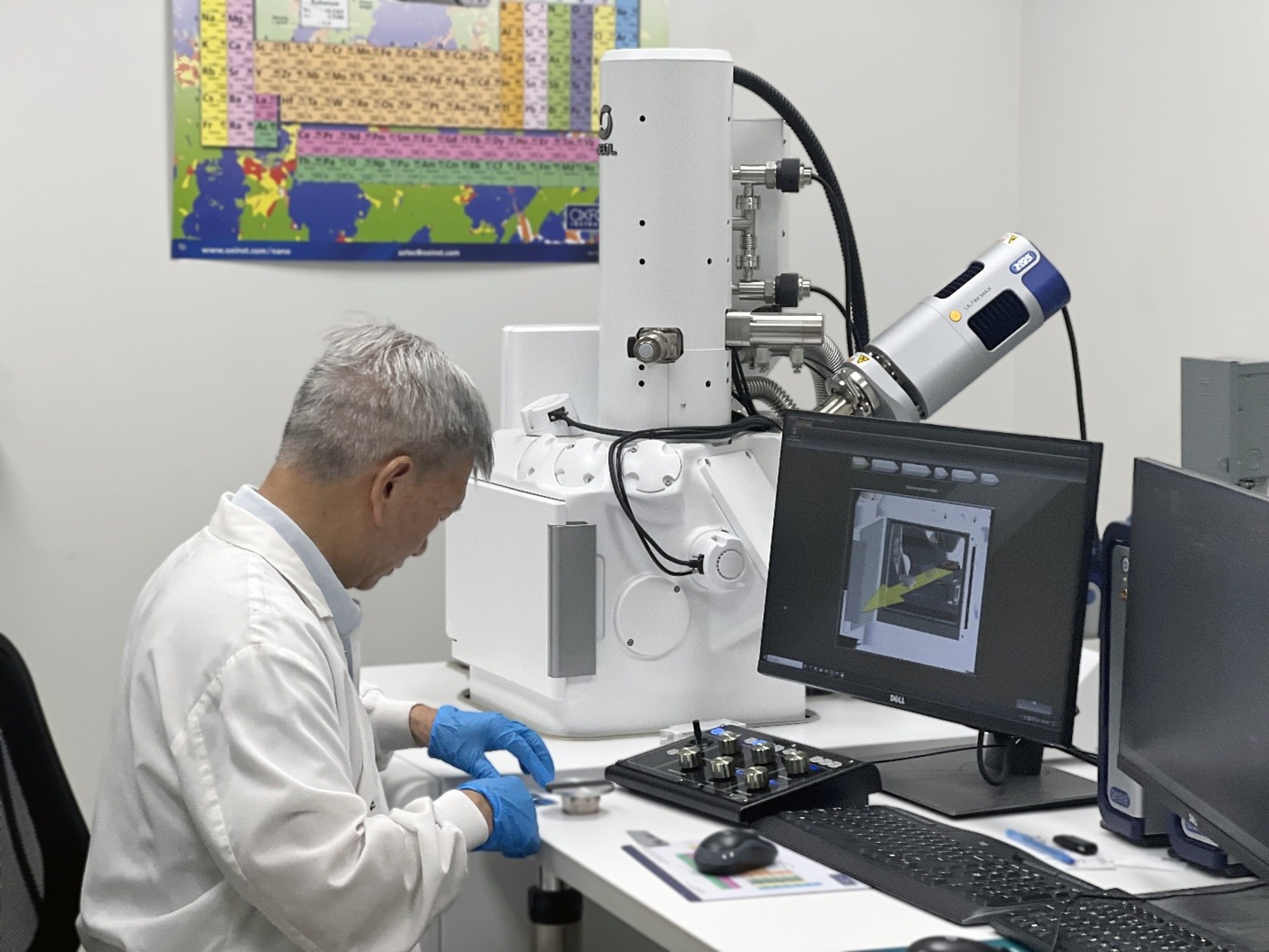

EBSD, or Electron Backscatter Diffraction, is a powerful technique used to analyze the grain structure of a material. It’s typically an accessory attached to a Scanning Electron Microscope (SEM), allowing scientists and engineers to examine grain orientation, phase distribution, and more. (Learn more about SEMs and how they work here: What is SEM Analysis and Why Is It Important?).

EBSD is widely used in materials science and metallurgy. It helps researchers understand and predict how a material will perform under various conditions, making it a valuable tool for everything from quality control to failure analysis.

How Does EBSD Work?

EBSD operates by directing a focused electron beam at a tilted sample inside a vacuum chamber. As the beam strikes the crystalline structure of the material, electrons are diffracted in patterns that depend on the orientation of the sample’s grains.

These diffracted electrons hit a detector, usually a phosphor screen, that converts the electron pattern into an image. This image reveals the orientation of the grains in the microstructure.

The system consists of three main components: The electron beam, the sample, and the detector. All of these are housed within a sealed chamber that maintains a vacuum, preventing air molecules from interfering with the electron beam. Some SEMs introduce a small amount of gas to create a low-vacuum environment, which helps reduce sample charging, the buildup of electric charge on non-conductive materials.

Why EBSD Matters: Applications and Use

The microstructure of a metal, its internal structure at the microscopic level, includes grain size and shape, phase composition, and defects. These features significantly influence a material’s physical, electrical and mechanical properties.

EBSD provides detailed information, including:

- Grain orientation

- Grain boundary locations

- Phase identification and distribution

- Crystallographic texture

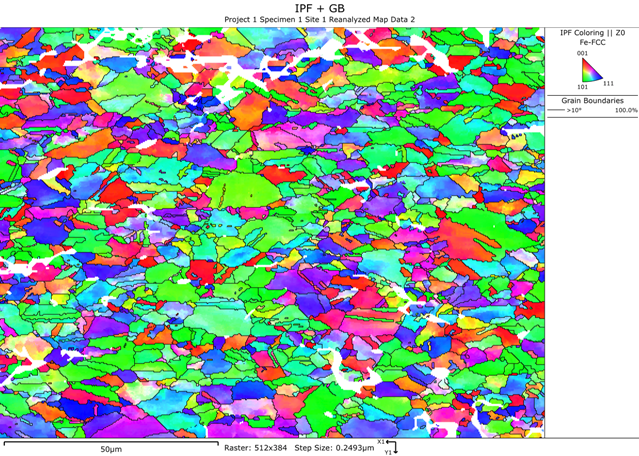

Displayed above is an example of a stainless-steel microstructure captured using Electron Backscatter Diffraction (EBSD). The different colors represent the orientations of the atomic structures within each grain.

This makes EBSD particularly useful for evaluating how manufacturing processes (like rolling, forging, welding, or heat treatment) affect material properties. It also plays a key role in failure analysis, such as identifying grain boundaries that may be vulnerable to corrosion or cracking. The stainless-steel sample shown above was taken from a failed fastener used in a deep-water application. In this case, we were examining the grain structure for the presence of brittle alpha and martensite phases.

In Summary

EBSD is a vital technique in the field of materials characterization. By analyzing the microstructure of metals, it provides insights that are essential for predicting performance, improving processes, and solving engineering problems

How Secat Can Help

At Secat, Inc., we specialize in SEM-EBSD analysis and materials characterization services for a variety of industries, including aerospace, automotive, and manufacturing. Our field emission-SEM has a fine beam size and high beam current that makes it ideally suited for EBSD measurements. Whether you’re troubleshooting failure, examining the evolution of the grain structure during extrusion processing, or exploring grain structure after welding, we can help.

Let our experienced metallurgists and advanced imaging tools support your next project.

Contact Secat today to discuss how EBSD and other analytical techniques can add value to your materials research or production processes.