In industries ranging from aerospace to automotive and even everyday applications like machinery and structural components, metal fatigue is often a dangerous phenomenon. It’s the gradual weakening of a material, typically a metal, due to repeated loading and unloading cycles over time. Despite its significance, metal fatigue is not always immediately visible, which can lead to catastrophic failures if not properly understood or addressed. In this blog, we will dive deep into what metal fatigue is, how it happens, and what can be done to prevent it.

What is Metal Fatigue?

Metal fatigue refers to the progressive and localized structural damage that occurs when a metal is subjected to repeated cycles of stress and strain. Unlike a one-time failure, which might result from a singular overload event or a defect, metal fatigue is a gradual process. Over time, the repeated stress causes microscopic cracks to form in the material. As these cracks grow, they can eventually lead to complete structural failure, often without warning.

Key Characteristics of Metal Fatigue:

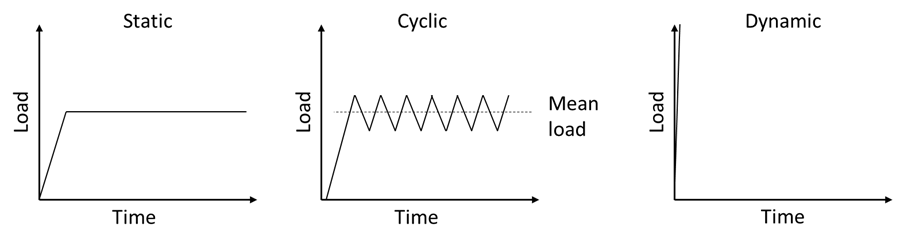

- Cyclic Loading: Metal fatigue is driven by fluctuating stress, at levels typically well below the ultimate strength of the metal.

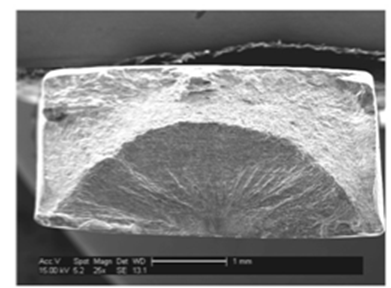

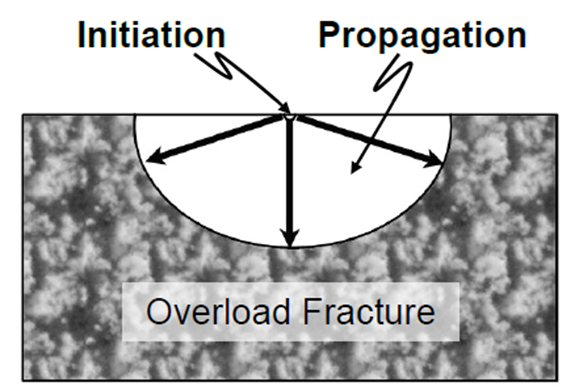

- Crack Initiation: A small crack forms at a surface or internal defect in the metal after a certain number of loading cycles. At higher cyclic stresses, the crack will form sooner than if the stress cycles are lower.

- Crack Propagation: After the crack initiates, the crack will begin to grow, the rate at which is related to the size of the crack and the cyclic stress levels.

- Failure: Once the fatigue crack reaches a certain size, the part may fail by either exceeding the UTS in the remaining ligament or through the process of unstable crack propagation known as fracture toughness.

“High cycle fatigue of AA6082 and AA6063 aluminum extrusions ” by Nicholas E. Nanninga

Factors Influencing Metal Fatigue

Several factors can influence how quickly metal fatigue occurs and how severe the damage can be:

- Stress Amplitude: The greater the fluctuation between the maximum and minimum stress, the more rapidly metal fatigue will develop. High-stress amplitudes lead to faster crack initiation and growth.

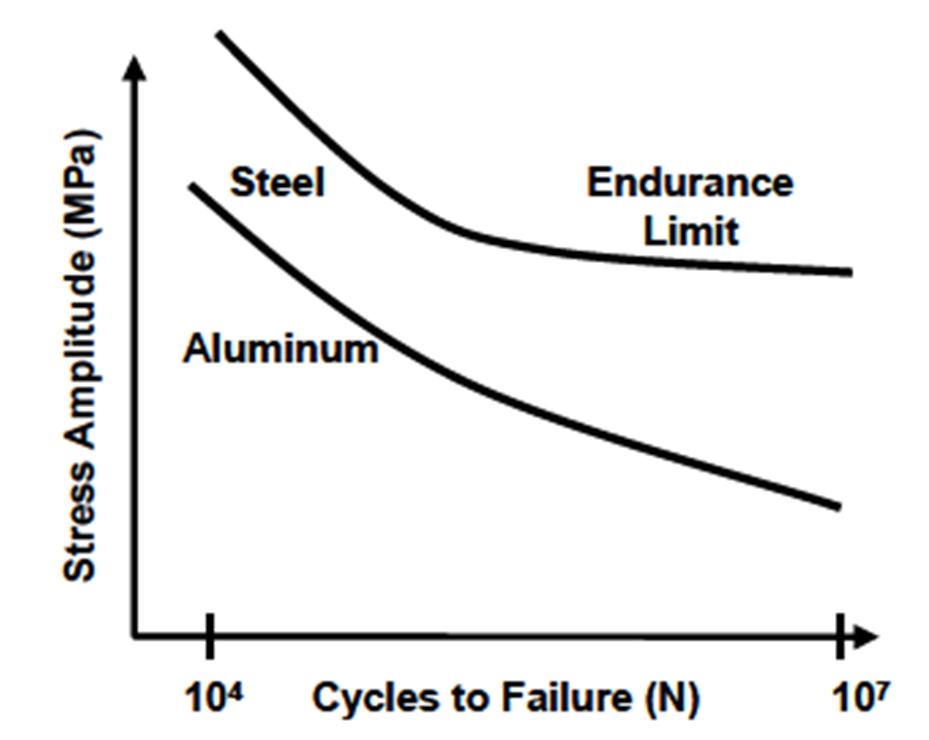

- Material Properties: Different metals respond differently to fatigue. For example, high-strength steels and titanium alloys tend to resist fatigue better than aluminum alloys, although the latter will still perform well under many conditions.

- Surface Finish: A smooth surface finish can delay the onset of fatigue. Conversely, rough or poorly-machined surfaces are more prone to forming microcracks sooner. Further, residual stresses play an integral role in the fatigue behavior of a component in either a favorable or unfavorable way depending on the state of the stress.

- Environment: Corrosive environments, such as salty air or acidic conditions, can promote crack initiation and accelerate crack growth, causing the phenomenon of corrosion-fatigue.

Consequences of Metal Fatigue

Metal fatigue can have serious, sometimes catastrophic, consequences. A classic example is the failure of a jet wing due to fatigue cracks that developed over time. Because metal fatigue can often occur without warning, failure may happen with no immediate indication, leading to severe consequences in critical applications like aircraft or bridge structures.

In automotive components, fatigue failure can cause the sudden breaking of parts like suspension arms or wheels. In manufacturing, a fatigued machine component can lead to downtime, repair costs, or even total machinery failure.

Common consequences of fatigue failure include:

- Loss of structural integrity: Even small cracks can dramatically reduce the load-bearing capacity of a component.

- Safety hazards: In aerospace, automotive, and civil engineering, fatigue can lead to loss of life or significant property damage.

- Cost implications: Fatigue failure often leads to expensive repairs and replacements, along with potential downtime and productivity loss.

How to Prevent Metal Fatigue

Various strategies can help minimize the effects of fatigue and extend the lifespan of metal components.

- Design Considerations:

- Reduce Stress Concentrations: Sharp corners, notches, and sudden changes in shape act as stress concentrators and can lead to premature fatigue failure. Rounded edges and uniform geometry help distribute stress more evenly.

- Use Materials with Higher Fatigue Resistance: Engineers can choose materials that are better suited to withstand cyclic loading. Steels, titanium alloys, and certain composites are often used in high-fatigue applications.

- Surface Treatments:

- Shot Peening: This process involves bombarding the material surface with small metal balls to induce compressive residual stresses, which can delay crack initiation.

- Hard Coatings: Coatings like nitriding or carburizing can increase surface hardness, reducing the likelihood of crack formation.

- Surface Finishing: Polishing or grinding metal surfaces to smooth finishes can also reduce the risk of fatigue cracks forming at surface defects.

- Fatigue Testing:

- S-N Curve (Wöhler Curve): The S-N curve is a graphical representation of the relationship between the number of cycles a material can withstand and the applied stress. By conducting fatigue tests, engineers can predict how long a material will last under specific conditions. High-Cycle tests (s-N) are typically performed on smooth samples at lower stress amplitudes and higher cycles to failure. Whereas Low-Cycle fatigue tests (e-N) are generally performed on smooth samples at high strain amplitudes and exhibit lower numbers of cycles to failure.

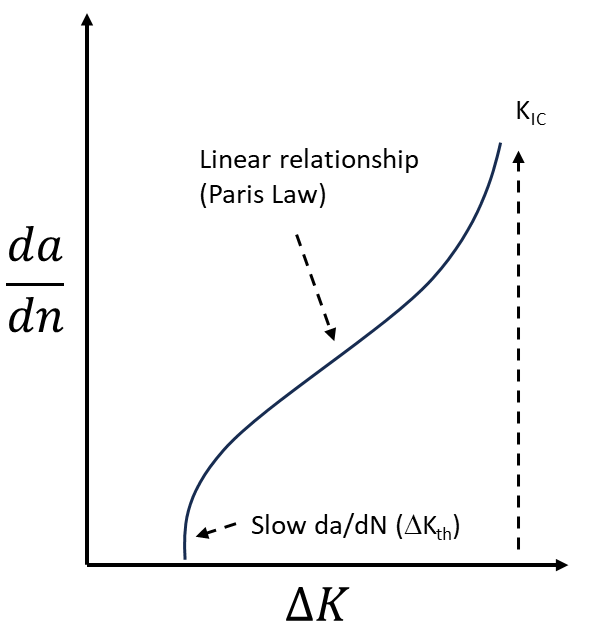

- Fatigue crack growth (DK vs da/dN): These tests are used to evaluate the performance of a component under the assumption that a fatigue crack or crack-like defect is present. In this case, the stress intensity at the tip of the crack (DK) is controlled and the rate of crack growth (da/dN) is measured. At low DK, the crack will grow very slowly, at moderate DK values a linear relationship is found between DK and da/dN (Paris Law). At high DK values, the fracture toughness will be nearly exceeded, and the crack will grow very rapidly. Components that are designed according to this method can be routinely inspected by NDT techniques to ensure the cracks are growing at predictable rates and parts can be removed or repaired if cracks becomes too large.

- Proper Maintenance Practices:

Regular maintenance schedules ensure that any early signs of fatigue are identified before they lead to failure. Timely repairs and replacements can save lives and prevent costly breakdowns.

Conclusion

Metal fatigue is a critical consideration in any application where metals are subject to repeated stress cycles. From aerospace to automotive and industrial machinery, understanding and managing metal fatigue is essential to ensuring safety, reliability, and longevity. With proper design, material selection, maintenance, and testing, the risks associated with metal fatigue can be minimized.

Secat is a proven leader in understanding and managing risk associated with fatigue in metal components. We not only perform the basic testing needed to certify that a material is safe for a fatigue application, but we assist customers with developing fatigue testing solutions for non-common applications such as fretting-fatigue in bending. Furthermore, customers come to Secat looking for 3rd party expert testimony and test method development to ensure parts in service are safe from fatigue and failure.

Contact Secat for Fatigue Testing needs.