Person of Interest

Chris Devadas, VP of Technology, Hydro Aluminum/Secat, Inc. Board Member

Chris has been in the Aluminum Industry since 1989 and with Hydro Aluminum since 1997. He describes his career objective and history as follows;

“To promote Aluminum as the most versatile material for the demands of the next generation of

challenges, especially the Auto-sectors demand for novel solutions for light weighting and superior

performance. Held positions in management of technology, research & development, and industrial implementation of new solutions, utilizing proven manufacturing management techniques and

experiences, relentless drive towards performance improvement and customer satisfaction and focus towards margin and bottom-line management. My focus has been in aluminum casting and extrusion processes, quality control and project management. In depth experiences also in technical customer service, sales and marketing areas.”

What brought you to the Board of Directors of Secat?

I have been involved in the field of Aluminum Application research and technology for the last 25

years. From the inception of Secat I have been directly or indirectly involved with Secat activities,

participating in consortium R & D programs headed by Secat.

In your opinion, what makes Secat unique/special in the industry?

Secat is located in the middle of the Aluminum Belt. Most of the major producers and consumers of Aluminum and Aluminum Alloys are located with a distance of less than 200 miles from Secat. This provides Secat a unique opportunity to support the needs and requests of these aluminum

companies in terms of lab support, technical support and R&D partnership. There is virtually very few stand alone lab and technical support organization in North America that can fill the void of downsizing of technical/metallurgical resources that has taken place in Aluminum industries, while Secat stands out as the only one that can fill this void.

Secat has built up impressive Aluminum metallurgical competence and state of the art equipment to provide high level support to the industry.

What is the most important/exciting development you see in the future for Secat?

The Auto industry has been a prime mover in increasing the usage of Aluminum this has led to

increased demand for new and better performing Aluminum products. Since Secat has

demonstrated capabilities to provide high level technical support to its customers, I see tremendous demand for the services that Secat offers to the industry and possibilities for forming or participating in R & D partnerships that support Auto industry demands.

Tell us something about yourself that people may not know and anything else you would like to

share.

I have had the unique opportunity to live and work in 4 different continents, and several different

cultures. This has enabled me to appreciate and savor diversity and the experience that it provides

to think in both local and global terms.

My introduction to the US was through Louisville Kentucky and hence I am a strong supporter of the Kentucky and Louisville college teams.

#ChrisLovesAluminum

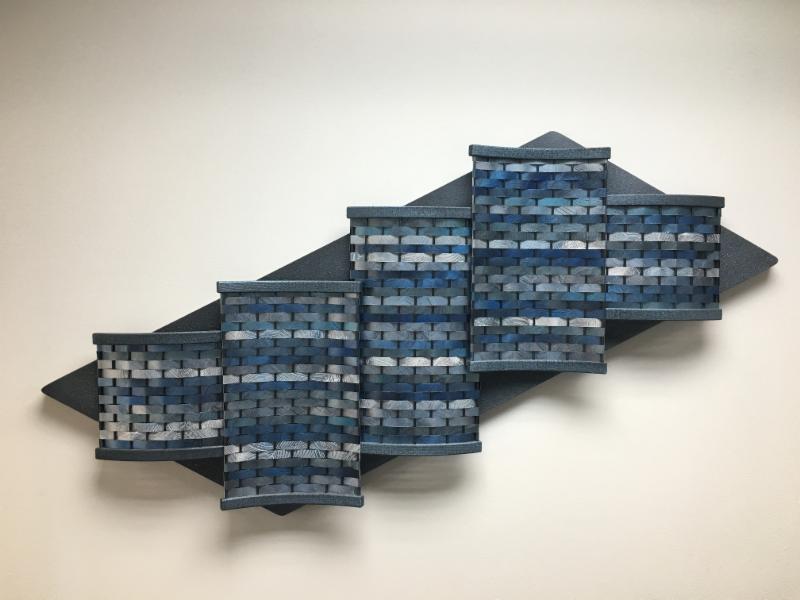

Wendy Bernard and James Mosier weave aluminum to create stunning wall sculptures, baskets and vessels – like the one featured here that hangs in the Secat, Inc. office entryway. Their woven works of art are showcased at art shows around the country and they have been commissioned to weave large- scale pieces for both residential and corporate clients.

Wendy Bernard and James Mosier weave aluminum to create stunning wall sculptures, baskets and vessels – like the one featured here that hangs in the Secat, Inc. office entryway. Their woven works of art are showcased at art shows around the country and they have been commissioned to weave large- scale pieces for both residential and corporate clients.